Views: 0 Author: Site Editor Publish Time: 2025-12-20 Origin: Site

In the operation system of power systems and industrial equipment, the arc extinguishing chamber is a core component that ensures the normal on-off of circuits and blocks arc hazards, which can be called the "safety heart" of the equipment. Its stable operation is directly related to the reliability of the entire power system, the continuity of production processes, and even the personal and property safety of on-site personnel. However, in practical applications, various failures of arc extinguishing chambers are common. Minor failures can lead to equipment shutdown and production interruption, while major ones can cause fires, explosions and other serious safety accidents. Today, we will analyze the typical failure cases of arc extinguishing chambers one by one, reveal the hidden dangers behind them, and bring you the ultimate solution to solve the problem from the root!

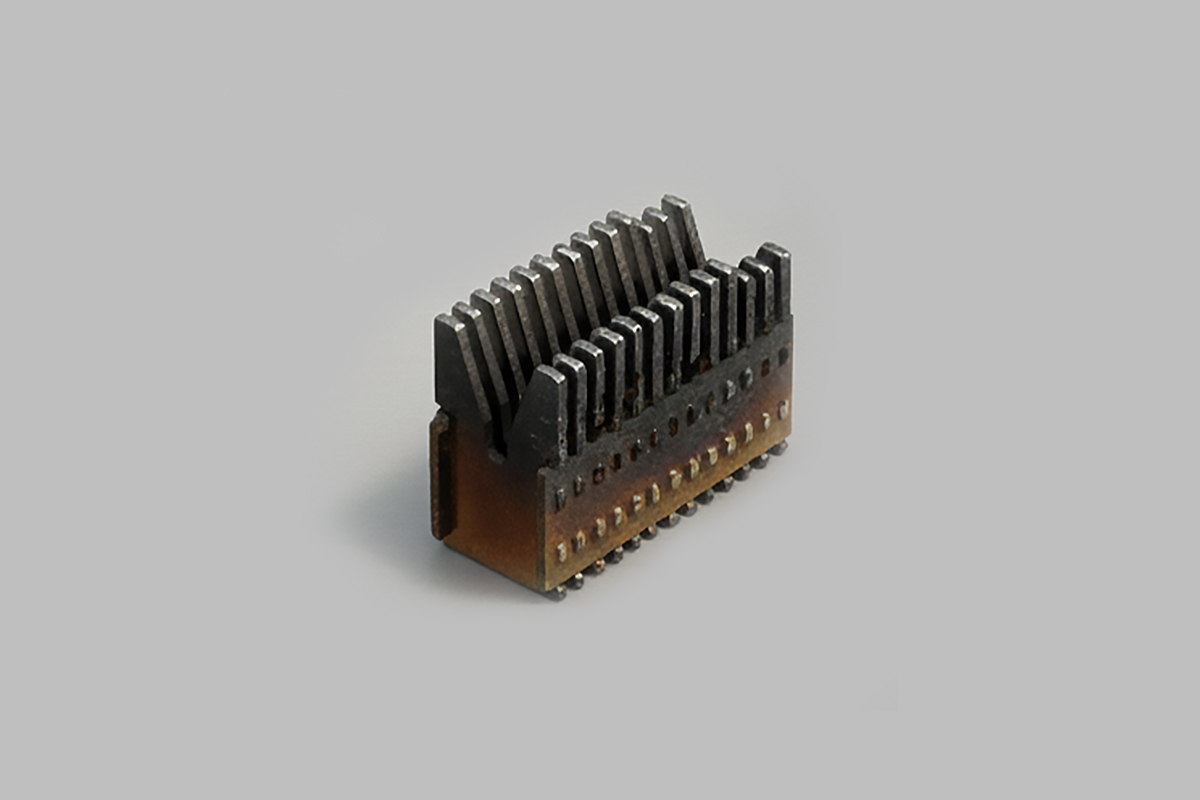

When a short circuit occurs in the circuit, extremely high arc temperature of thousands of degrees Celsius is generated instantly. This extreme high temperature, like "hellfire", directly impacts the metal components and insulating parts inside the arc extinguishing chamber. Under such intense thermal shock, the originally high-precision components will quickly lose their original shape: metal parts undergo plastic deformation, key contact surfaces fuse and adhere, and even some materials melt and flow away. This is by no means a gradual loss, but a "one-touch collapse" fatal failure — when the equipment needs to perform a power-off interruption operation, the deformed and adhered components cannot move normally, resulting in the circuit failing to be cut off in time, and the equipment is instantly paralyzed.

Imagine: In a precision industrial production line, a sudden equipment shutdown may cause the entire production line to stop, resulting in huge economic losses every minute; in a power distribution system, failure to extinguish the arc in time after a short circuit will cause the arc to burn continuously, damaging busbars and switchgear, and even triggering large-scale power outages. This kind of "instant paralysis" failure not only has high repair costs but also brings unpredictable chain losses.

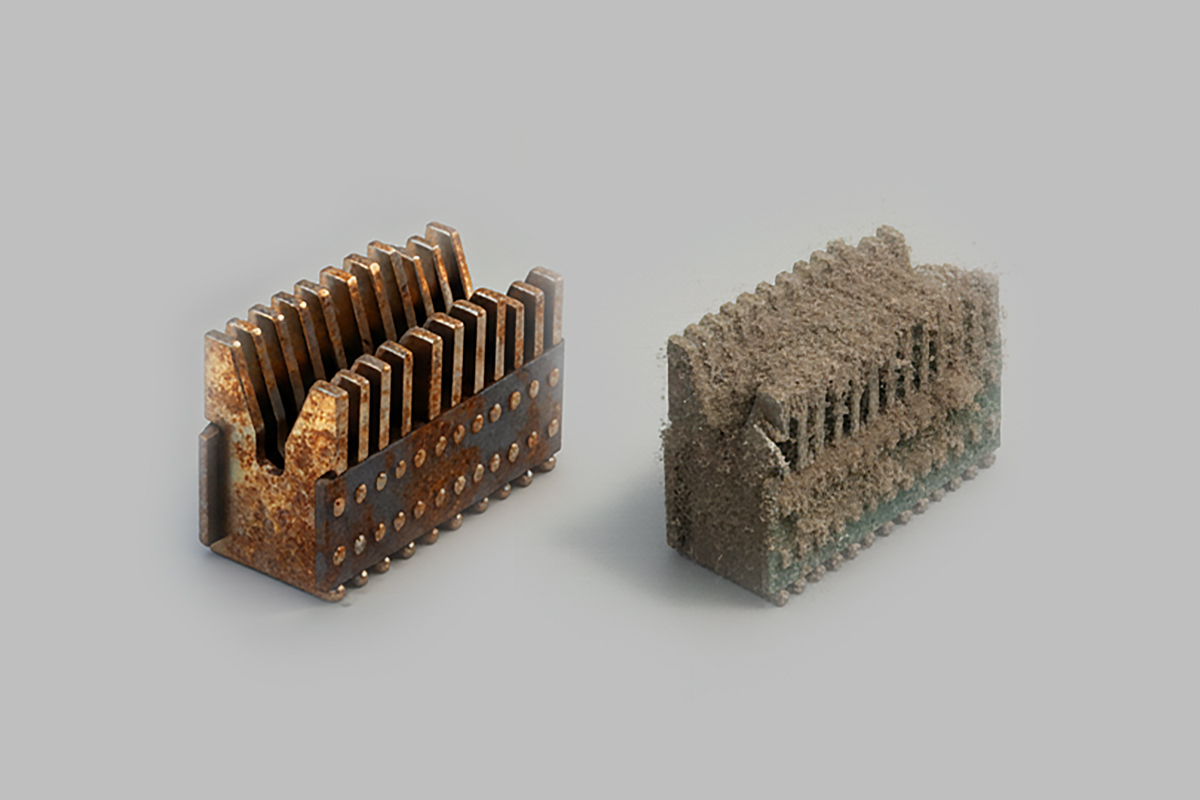

In many cases, the failure of the arc extinguishing chamber does not stem from major defects of core components, but from "small problems" hidden in details — rivet cracking and weld slag residue. During the long-term operation of the equipment, even slight vibrations during equipment start-up and shutdown, or low-frequency shaking of the surrounding environment, may become the "last straw that breaks the camel's back". Cracked rivets will gradually expand cracks under vibration and eventually lose their fixing function; residual weld slag may fall off, jamming the transmission mechanism or scratching the insulating surface.

These seemingly insignificant detail failures often trigger chain reactions: rivet fracture leads to loose components, loose components intensify vibration, which in turn causes more component damage, and finally leads to complete failure of the arc extinguishing chamber. What's more terrifying is that such failures are highly concealed and difficult to detect during daily inspections. Once they occur, they are a "fatal blow", putting the equipment in danger without warning.

The plating layer of the arc extinguishing chamber is like a layer of "protective armor", which undertakes the key role of resisting external corrosion, oxidation, and moisture intrusion. However, if the plating coverage is incomplete during the production process or the plating thickness does not meet the design standards, this layer of armor will be full of "holes". At this time, the protective capacity of the arc extinguishing chamber will be directly halved, and the substrate that should be tightly protected will be exposed to the outside, becoming a "target" for external erosion.

Sealing performance is another important line of defense for the arc extinguishing chamber to resist external damage. However, during long-term use, seal aging and plating peeling often form a "double blow", making the failure worse. On the one hand, the peeling of the plating layer exposes the substrate, which not only causes corrosion and rust but also accelerates the aging, hardening, and cracking of the seal; on the other hand, seal failure will cause pressure leakage, allowing external dust, moisture, and corrosive gases to seep into the arc extinguishing chamber.

The core mission of the arc extinguishing chamber is to extinguish the arc quickly and safely. The industry-recognized safety standard is: effective self-extinguishing within 30 seconds after flame removal. If the arc extinguishing chamber fails to meet this requirement, it means that the most critical safety function is invalid. Scattered arcs will be like "out-of-control flames", which will not only burn the internal structure of the arc extinguishing chamber itself but also ignite flammable components such as surrounding cables and insulating materials, causing fires; more seriously, the arc may break through the equipment shell, resulting in personal electric shock accidents, and the safety risk soars to the peak in an instant.

Faced with these endless potential failures, do you really have to bear them passively? Losses from production interruption, costs of equipment maintenance, risks of safety accidents... All these could have been avoided!

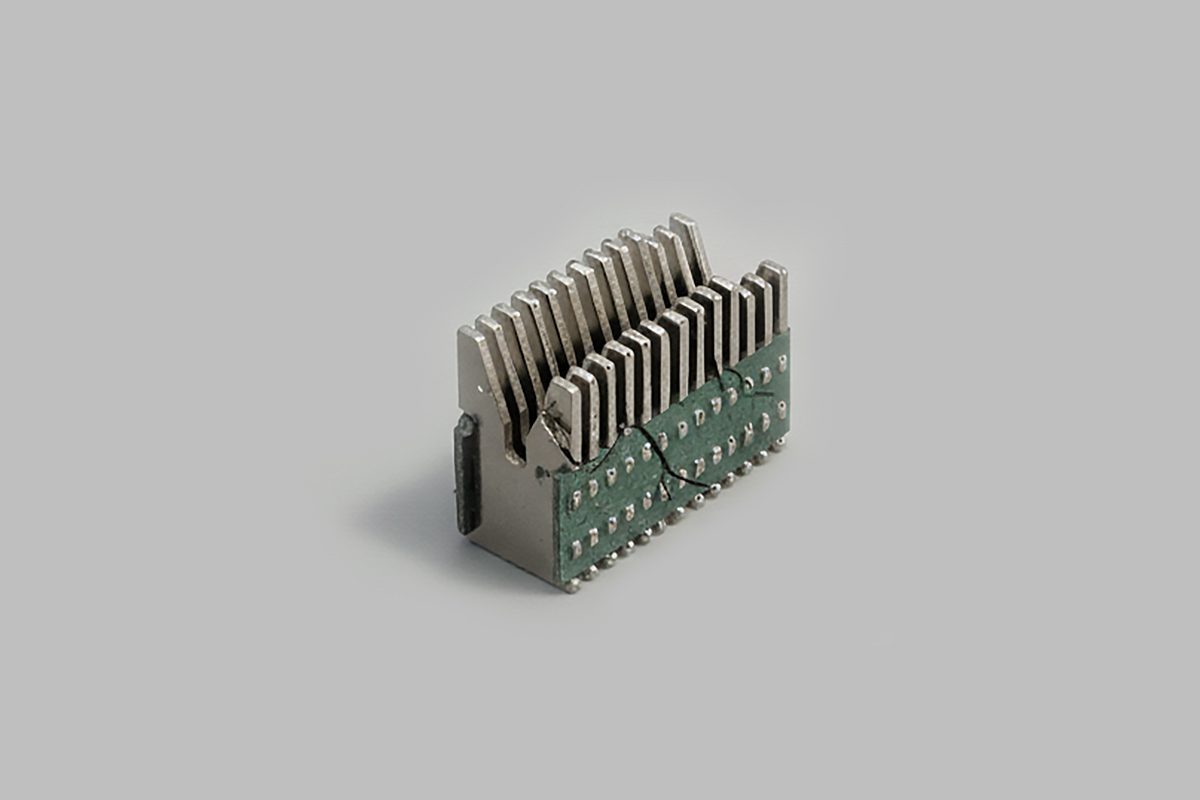

【 HAIPART Arc Extinguishing Chamber】—— Your Equipment's "Stabilizer" and Industrial Safety's "Guardian Angel"!

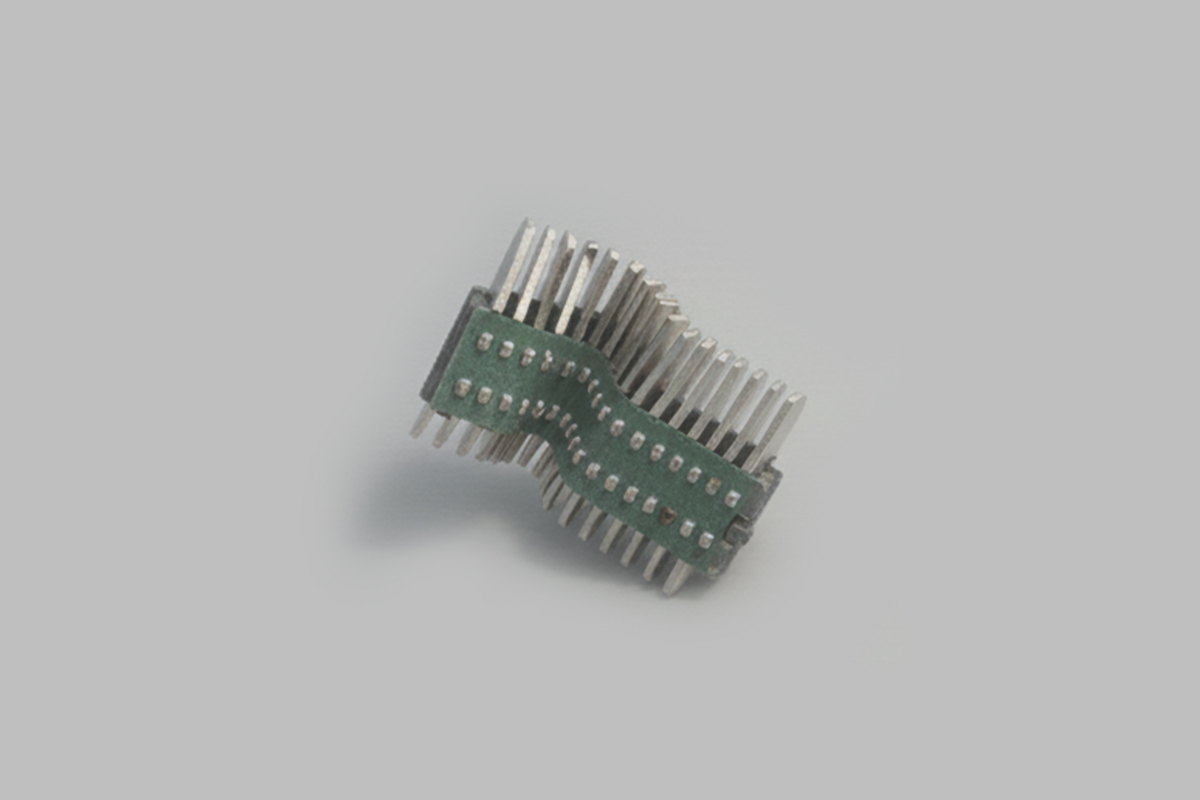

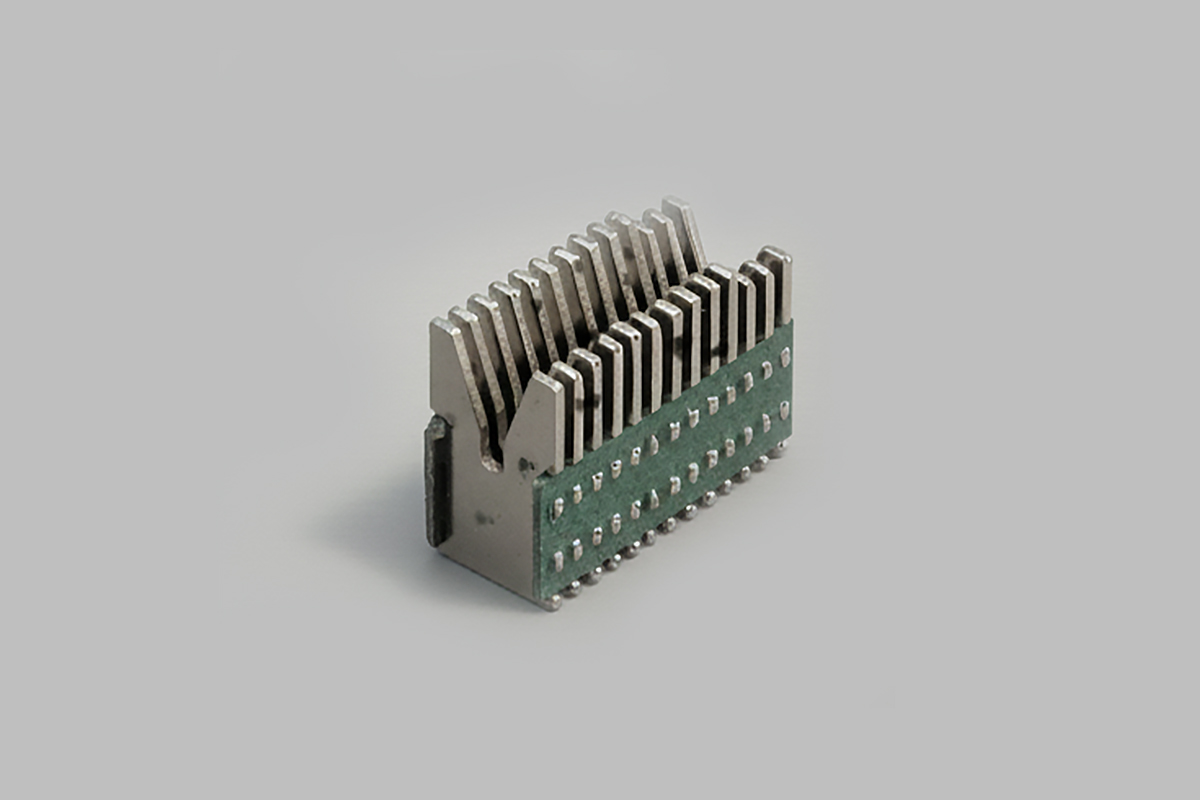

HAIPART arc extinguishing chamber adopts special high-temperature resistant alloy materials and advanced thermal protection structure design, which can calmly resist the extreme high-temperature impact caused by short-circuit arcs. After thousands of rigorous high-temperature tests and verifications, even in the arc environment of thousands of degrees Celsius, the internal components can still maintain their original shape and performance, without deformation, melting, or adhesion, ensuring that the equipment can smoothly complete the interruption operation in any emergency.

We adhere to the production concept of "millimeter-level precision" and implement strict quality control for every production link. Rivets are made of high-strength corrosion-resistant alloys and undergo special reinforcement treatment to eliminate cracking hazards; the welding process adopts automatic precision welding technology, combined with multiple weld slag cleaning processes to ensure smooth welds without residue. The finished products also need to go through multiple rigorous inspections such as vibration tests and fatigue tests to ensure long-term stable and reliable operation, leaving no safety dead ends in details.

HAIPART innovatively adopts the "triple plating process": first, the substrate is pre-treated to remove impurities, then vacuum coating technology is used to achieve full-dimensional coverage of the plating layer, and finally, strengthening treatment is carried out to improve adhesion and thickness. The plating thickness far exceeds industry standards, with uniform coverage without dead ends, and the protective capacity is doubled. It can effectively resist various external hazards such as moisture, corrosive gases, and dust, ensuring that the substrate is not eroded for a long time, and the service life of the arc extinguishing chamber is greatly extended.

To solve the problem of seal failure, we use military-grade sealing materials and design a "double seal + pressure compensation" structure. The seals have strong aging resistance and corrosion resistance, and are not easy to harden and crack after long-term use; the double seal structure combined with pressure compensation design can effectively block the infiltration of external moisture and dust, balance internal pressure, avoid pressure leakage, keep the internal environment of the arc extinguishing chamber clean and dry, and eliminate failures caused by rust and pollution from the root.

HAIPART arc extinguishing chamber is equipped with an independently developed high-efficiency arc extinguishing system, optimizing the internal air channel structure and arc extinguishing medium formula, which can quickly guide the arc and dissipate arc energy. Tested by authoritative institutions, stable self-extinguishing can be achieved within 10 seconds after flame removal, far exceeding the industry standard requirement of 30 seconds. It completely eliminates the risk of scattered arcs and provides the most solid guarantee for equipment and personnel safety.

Failures of arc extinguishing chambers are never isolated "small problems", but "major hidden dangers" related to production safety and economic benefits. HAIPART arc extinguishing chamber always adheres to the goal of "zero failure", and comprehensively blocks all failure points from material selection, structural design to production process, allowing each piece of equipment to have a reliable "safety heart".