Views: 0 Author: Site Editor Publish Time: 2025-12-26 Origin: Site

You should know the main difference between an mcb and an mccb. They are used for different things and follow different rules. MCBs protect home and business circuits. They follow IEC 60898-1. MCCBs are for factories and big machines. They follow IEC 60947-2. The right breaker keeps your system safe. It must have the correct rating for fault protection. Haipart’s experience helps you get safe circuits. Look at the table below to see how many are used worldwide:

| Sector | Units Installed (2024) | Key Drivers |

|---|---|---|

| Residential | 900 million | Mandated mcb installation in new buildings |

| Commercial | 700 million | Stable power supply for businesses |

| Industrial | 400 million | Heavy-duty machinery protection with mccb |

MCBs work best in homes and small shops. They keep low-voltage wires and small devices safe.

MCCBs are made for factories and big buildings. They can handle strong currents and protect big machines.

Always look at the breaking capacity ratings (Icu and Ics) before you pick a breaker. This keeps everyone safe if something goes wrong.

Use the right IEC rules: IEC 60898-1 is for MCBs and IEC 60947-2 is for MCCBs. This helps you pick the right one.

Check and take care of your breakers often. This stops problems and helps them last longer.

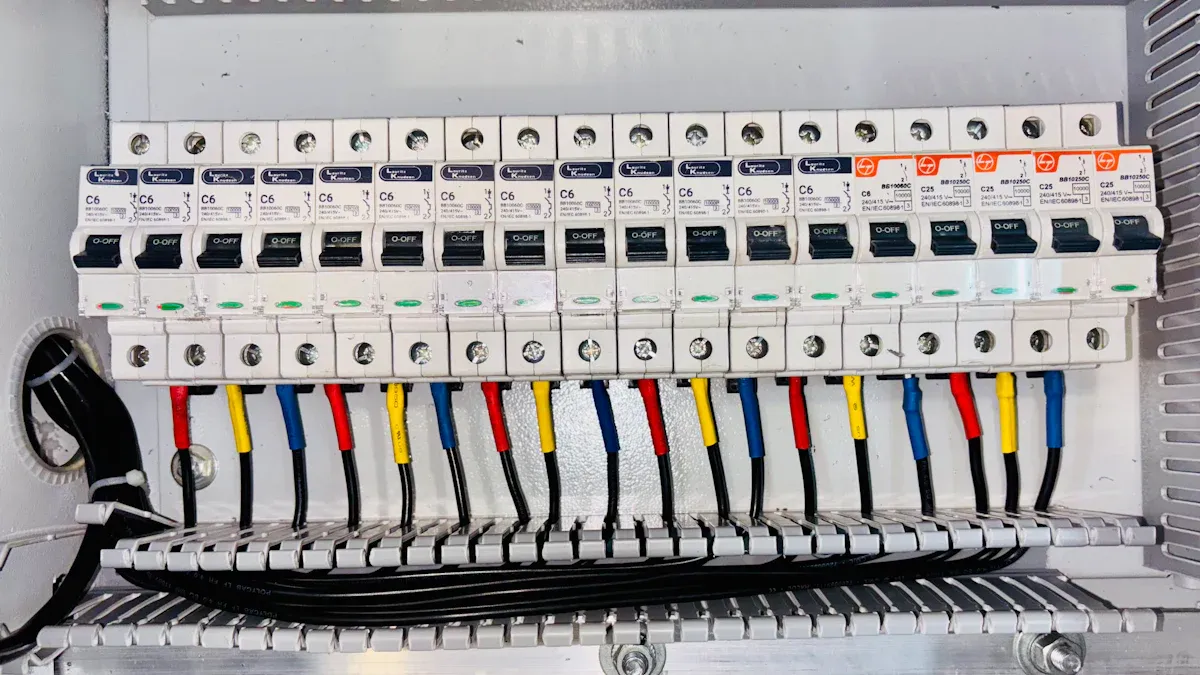

A miniature circuit breaker helps protect your home or office. It stops electrical problems like overloads and short circuits. This device is small and fits inside a distribution box. It works best for low-voltage circuits. It can handle up to 100 or 125 amps. You often see these in lighting circuits and with small appliances. The Haipart miniature circuit breaker uses new technology to keep you safe. It has silver contacts. These help lower resistance and stop arcs fast. You can install it easily. You can also turn it on or off by hand.

Here is a table that shows the main features of miniature circuit breakers compared to molded case circuit breakers:

| Feature | Molded Case Circuit Breakers (MCCBs) | Miniature Circuit Breakers (MCBs) |

|---|---|---|

| Structure and Size | Larger, rated from 63A to 2500A | Smaller, rated from 1A to 63A |

| Application Areas | Industrial and commercial systems | Residential and small commercial |

| Protection Functions | Overload, short-circuit, leakage | Mainly overload and short-circuit |

| Installation Method | Installed in distribution cabinets | Installed on distribution box rails |

| Price | Higher due to capacity and functions | Relatively cheaper |

Tip: Pick a miniature circuit breaker for simple circuits. It is good for everyday electrical safety.

A molded case circuit breaker protects big machines and main power lines. This device is bigger and stronger than a miniature circuit breaker. You find it in factories and large buildings. It works in motor control centers too. Molded case circuit breakers handle more current. They work from 16 amps up to 1600 amps or more. They can stop very high fault currents. Some can handle up to 200,000 amps. You can mount them up or sideways. You can add things like shunt trips or extra contacts.

Here is a table that shows important technical specifications for molded case circuit breakers:

| Specification Type | Details |

|---|---|

| Rated breaking capacity (Icu) | Up to 200,000 amps at high voltages |

| Rated operating breaking capacity (Ics) | High values for industrial safety |

| Rated Voltage | Up to 690V AC (insulation voltage: 1000V) |

| Rated Current | 10A~630A (frame sizes: 125/250/400/630A) |

| Breaking Capacity | 15-50kA (Icu/Ics: 15/10 to 50/35kA @ 400V) |

| Standards | IEC 60947-2 |

| Installation | Vertical/horizontal mounting; accessories |

Note: Use a molded case circuit breaker for high-power circuits. It is best for heavy-duty jobs.

You need to know where each breaker works best. Miniature circuit breakers are for homes, offices, and small businesses. They keep lights and small appliances safe. They stop overloads and short circuits. Molded case circuit breakers are for factories and big buildings. They protect heavy machines and main power lines. They can handle high currents.

Here is a table that compares the current range and typical applications for both types:

| Type | Current Range | Typical Applications |

|---|---|---|

| MCB | Up to 100–125 A | Residential homes, offices, light commercial |

| MCCB | 16 A to 1600 A or more | Industrial plants, main distribution boards, motor control centers, large commercial installations |

You see miniature circuit breakers in homes and offices. You see molded case circuit breakers in factories and large buildings.

Here is another table that shows the most common applications and use cases:

| Type | Application Area | Current Capacity | Key Role |

|---|---|---|---|

| MCB | Residential | Up to 63 Amps | Protects low-voltage circuits and appliances from overcurrent and short circuits |

| MCCB | Commercial/Industrial | 15 Amps to 2500 Amps | Protects high-capacity electrical circuits and manages power distribution across extensive systems |

Miniature circuit breakers are used in homes for lights and small appliances.

Molded case circuit breakers are needed in factories for machines and big appliances.

You should always pick the right breaker for your circuit. Match the breaker to your current and voltage needs. Miniature circuit breakers are best for low-current, low-voltage circuits. Molded case circuit breakers are best for high-current, high-voltage circuits.

Standards help you pick the right circuit breaker. IEC 60898-1 is the rule for miniature circuit breakers, or MCBs. This rule is for devices that protect homes, offices, and small businesses. IEC 60898-1 works for low-voltage circuits up to 440V AC. It also covers current ratings up to 125A. The rule makes sure your MCB will trip if there is too much current or a short circuit. It checks if the device can handle heat and last a long time. The rule also tests if it can stop arcs. MCBs are tested for overcurrent protection, how fast they trip, and how long they last. IEC 60898-1 says the product must have clear labels and not rust. These rules help you trust your MCB to keep your home or office safe.

| Standard | Title | Scope | Voltage Rating | Current Rating | Breaking Capacity |

|---|---|---|---|---|---|

| IEC 60898-1 | Circuit breakers for overcurrent protection for household and similar installations. | Low-voltage circuit breakers for residential, commercial, and light industrial applications. | Up to 440V AC | Up to 125A | Typically 6kA to 10kA |

IEC 60947-2 is the rule for molded case circuit breakers, or MCCBs. This rule is for devices used in factories and big buildings. It also covers heavy-duty systems. IEC 60947-2 works for circuit breakers with voltage up to 1000V AC and 1500V DC. It covers current ratings from 125A up to 6300A or more. The rule checks if MCCBs can handle very high fault currents, sometimes up to 200kA. IEC 60947-2 tests breaking capacity, how long the device lasts, and if it can stop arcs. It also has extra rules for selectivity and coordination. MCCBs are tested to work well in tough places. This rule makes sure your MCCB can protect big machines and main power lines.

| Standard | Title | Scope | Voltage Rating | Current Rating | Breaking Capacity |

|---|---|---|---|---|---|

| IEC 60947-2 | Low-voltage switchgear and controlgear - Part 2: Circuit breakers. | Circuit breakers for industrial and heavy-duty applications. | Up to 1000V AC and 1500V DC | Typically exceeds 125A, often used up to 6300A | Typically 15kA to 150kA |

You need to use the right rule for your job. IEC 60898-1 is for MCBs in homes, offices, and small businesses. IEC 60947-2 is for MCCBs in factories and big buildings. If you pick an MCB, it is tested for lower currents and basic overcurrent protection. If you need to protect big machines or main panels, you need an MCCB that follows IEC 60947-2. This rule makes sure the device can handle high fault levels and hard jobs. Both rules test icu and ics. These show how much fault current the breaker can stop and how well it works after a fault. You should always check the icu and ics ratings before picking a breaker. These ratings help you know if the device will keep your system safe during a fault. IEC 60947-2 also has special features for selectivity. This helps you use many breakers together in a big system. When you follow the right IEC rule, your electrical system will be safe and work well.

You should know what icu means when picking a circuit breaker. icu is the ultimate breaking capacity. It shows the biggest short-circuit current the breaker can stop once. The icu value is measured in kiloamperes rms. The icu test uses one shot at the rated fault current. Both iec 60898-1 and iec 60947-2 need this test. You will see icu on every mcb and mccb label. It tells you how much fault current the breaker can safely handle.

| Term | Definition | Measurement Method |

|---|---|---|

| Icu | Ultimate breaking capacity; maximum short-circuit current a breaker can interrupt once. | Measured in kiloamperes rms; one-shot test at rated fault current. |

You also need to know about ics. ics stands for service breaking capacity. It shows the highest short-circuit current the breaker can clear more than once. The breaker still works well after these tests. ics is always a part of icu. You test ics by running three quick operations at the ics level. After each test, you check insulation, tripping, and heat. Both iec 60898-1 and iec 60947-2 require this test. You will find ics on every breaker label. It shows how reliable the breaker is after a fault.

| Term | Definition | Measurement Method |

|---|---|---|

| Ics | Service breaking capacity; expressed as a percentage of Icu, indicating the current level the breaker can clear repeatedly. | Tested through three back-to-back operations at the Ics level, followed by checks on insulation, tripping, and heat performance. |

You must check breaking capacity before picking an mcb or mccb. icu and ics ratings help you know if the breaker will protect your system during a fault. For mcb, iec 60898-1 sets icu from 6 kA to 10 kA. For mccb, iec 60947-2 allows icu up to 150 kA. ics usually ranges from 25% to 100% of icu. High ics means the breaker can clear faults many times and keep working. You want a high ics to icu ratio for safety and fast recovery. Both iec 60898-1 and iec 60947-2 require you to check short-circuit ratings. These ratings show the most current the breaker can stop. You must use the right rating for your installation. If you work in a factory, you need a breaker with high breaking capacity. If you protect a home, a lower rating is enough. Always follow iec rules for selectivity and safety.

| Rating Type | Typical Range | Description |

|---|---|---|

| Icu | 10 kA to 150 kA | Maximum fault current the breaker can interrupt without damage. |

| Ics | 25% to 100% of Icu | Service short-circuit breaking capacity, indicating reliability after fault interruption. |

Tip: Always check the breaking capacity and short-circuit ratings on the label. This step keeps your electrical system safe and reliable.

| Aspect | Description |

|---|---|

| Icu (Ultimate Short-Circuit Breaking Capacity) | Shows the most fault current the device can stop without damage. |

| Ics (Service Short-Circuit Breaking Capacity) | Shows the most fault current the device can stop under service conditions. |

| High Ics/Icu Ratio | Means the breaker is reliable after a fault. This is important for safe operation and quick recovery. |

| Testing Standards | Following IEC 60947-2 makes sure devices meet safety rules. |

| Selection Criteria | Includes short-circuit calculations and selectivity needs to pick the right device type. |

You need to look at the main technical features when you compare circuit breakers. The table below shows the most important specifications side by side. This helps you see the differences quickly.

| Specification | MCB | MCCB |

|---|---|---|

| Interrupt Current Rating | Up to 1800A | 10k – 200k Amperes |

| Rated Current | 6 – 125A | 0.5 – 160A |

| SC Breaking Capacity | <25kA | <50kA |

| Rated Voltage | 400V | 440V, 500V, 690V |

| Impulse Voltage | 4kV | 6kV – 8kV |

| Pollution Degree | 2 | 3 |

| Curves | B, C, D | B, C, D, K, Z, MA |

You can use this table to match the right breaker to your needs. For homes and small offices, you often choose an mcb. For factories and large buildings, you usually need an mccb.

MCBs follow IEC 60898-1 for residential and commercial applications.

MCCBs are tested according to IEC 60947-2, mainly for industrial use.

You want your circuit breaker to last a long time and work well. MCBs have a simple design. They need little maintenance. You can trust them for many years in homes and offices. MCCBs have a stronger build. They handle tough jobs in factories. You may need to check them more often, especially if you use them in heavy-duty systems. Both types have clear labels and strong cases. You should always follow the maker’s guide for checking and cleaning. This keeps your system safe and working.

Tip: Regular checks help you spot problems early. Clean dust and check for loose wires to keep your breaker in top shape.

First, think about what you need before you pick a breaker. Check how much current your circuit uses each day. See if you have machines that make power surges. Look at where you will put the breaker. A house, small business, or factory needs different things. Always check local rules like the NEC. Make sure your breaker follows these rules. You should also check the breaking capacity. This shows how much fault current the breaker can stop. Think about the environment too. High heat, wet air, or dust can change how the breaker works. If you are not sure, ask a professional for help. They can help you pick the right breaker for your needs.

You must pick the right size breaker for short circuit safety. First, find out the highest current your circuit could get. For loads that run all the time, use only 80% of the breaker's rating. This helps stop heat problems. Make sure the interrupting capacity is as high as or higher than the fault current. This keeps your system safe if there is a problem. Think about the environment too. Wet air or high places can change how the breaker works. Some breakers let you adjust settings for overload and short circuit safety. Pick one that fits your needs. If you use the breaker in a factory or business, look for features like moisture resistance.

Follow these steps to pick the right breaker for your needs:

Find the frame size. This tells you the most current the breaker can handle.

Check the rated current. This is when overload protection starts.

Look at the ultimate short-circuit breaking capacity. Make sure it fits your needs.

Review the service breaking capacity. This shows how many times the breaker can stop a fault.

Check the voltage ratings. Match them to your circuit.

Pick the right curve type for your main use. B, C, and D curves work for different jobs.

Decide if you need extras like shunt trips or rotary handles.

Choose the right protection type. Over current and short circuit protection are common needs.

Think about other things like frequency, pollution degree, and isolation.

For homes, offices, or light industry, Haipart MCBs meet these needs. For heavy industry, pick an MCCB that fits your needs.

Tip: Always match your breaker to your needs. This keeps your system safe and working well.

You should know where to use MCBs and MCCBs. Each one is made for a special job. Here are some examples:

MCBs are found in home breaker boxes. They protect things like lights, computers, and TVs.

MCCBs are used in big places like malls and hospitals. You also see them in factories and power units.

MCBs keep home circuits safe from too much current or short circuits.

MCCBs protect strong machines and help spread power in factories.

The table below shows where you use MCBs and MCCBs:

| Setting Type | MCB Applications | MCCB Applications |

|---|---|---|

| Residential | Protects lighting, small appliances, electronics | N/A |

| Commercial | Safeguards lower voltage operations in businesses | Main protection for larger commercial installations |

| Industrial | N/A | Essential for high-capacity power distribution |

Tip: Pick MCBs for homes and small offices. Use MCCBs for big buildings and factories.

You need to choose the right breaker for your system. Look at these important things:

| Selection Criteria | Description |

|---|---|

| Current Rating | Makes sure the breaker trips at the right time to protect your equipment. |

| Type and Rating | Helps you match the breaker to your electrical system. |

| Electrical Coordination | Lets breakers work together for better safety and performance. |

| Physical Design | Affects how you install the breaker and how much space you need. |

| Additional Features | Includes options for extra safety and better performance. |

Check the current rating before you buy.

Make sure the breaker type fits your system.

Think about how breakers work together.

Look at the size and shape for easy setup.

Think about extra features for more safety.

Note: If you are not sure, ask an expert. The right breaker keeps your system safe and working well.

Some circuit breakers look the same but follow different rules. If you use an MCB when you need an MCCB, your system may not be safe. IEC 60898 is for MCBs in homes and small businesses. IEC 60947-2 is for MCCBs in factories and big buildings. If you mix them up, you might pick a breaker that cannot do the job. Always check the standard before you buy or use a breaker. This helps you get the right device for your needs.

Tip: Look at the product label and technical sheet. These papers tell you which standard the breaker uses.

You need to look at breaking capacity ratings. If you skip this, you put people and equipment in danger. If the interrupting capacity is too low, the breaker may not work during a fault. This can cause big damage and safety problems. You might have long downtime and repairs that cost a lot.

An MCCB with low breaking capacity can break badly during a fault.

This can make things unsafe and damage equipment a lot.

You may have to stop work for a long time and pay for repairs.

Always check the breaking capacity before you put in a breaker. This keeps your system safe and gives good protection.

Sizing mistakes happen a lot. You might choose the wrong breaker for your job. Sometimes, the wire size does not match the breaker’s amperage. This can make wires get too hot. Problems with grounding and labeling also make things unsafe. You must ground your system the right way to keep it safe. Do not put more than one wire in the same terminal on the bus bar. Loose wires can cause arcing and fires.

Picking the wrong type of circuit breaker for the job.

Using the wrong wire size with the breaker, which can make wires too hot.

Problems with grounding and labeling, which are important for safety.

Good grounding is needed for safety and for things to work right.

Do not put many wires in one terminal on the bus bar to stop loose wires and arcing.

Note: Always check your sizing and how you install things. Careful planning helps you avoid mistakes and keeps your electrical system safe.

When you pick between an mcb and an mccb, do these things: First, look at the rated current and voltage for your system. Next, check the ultimate and service breaking capacities. Then, make sure the number of poles fits your job.

You should know the standards and ratings before you put in any breaker. Haipart is known for being strong and reliable, so many people trust it. If your project is hard, ask a skilled electrician for help to stay safe and follow the rules.

You use an MCB for homes and small offices. You use an MCCB for factories and large buildings. MCBs handle lower currents. MCCBs handle higher currents and offer more protection.

Check the product label. If you see IEC 60898-1, you have an MCB for homes or small businesses. If you see IEC 60947-2, you have an MCCB for industrial or large commercial use.

Breaking capacity shows how much fault current your breaker can safely stop. If you pick a breaker with low breaking capacity, it may fail during a short circuit. Always match the rating to your system.

Yes, you can. Haipart MCBs work well for solar photovoltaic systems and electric vehicle charging. They offer fast protection and high reliability for these modern applications.