Views: 0 Author: Site Editor Publish Time: 2025-11-18 Origin: Site

Have you ever wondered what makes circuit breakers switch so quickly and safely? The secret lies in the operating mechanism. This crucial part controls how breakers protect electrical systems from faults.

Operating mechanisms ensure precise switching, influencing both protection and reliability. Different breakers use varied mechanisms tailored to their needs.

In this post, you’ll learn about the vital role of operating mechanisms, their types, and how they impact circuit breaker performance.

The operating mechanism is the core component that enables a circuit breaker to open and close its contacts swiftly and reliably. It serves as the bridge between the control commands and the physical switching action, ensuring the circuit breaker responds accurately to protective signals.

At its essence, the operating mechanism performs five critical functions:

Energy Transmission: Transfers stored energy to the breaker contacts to initiate opening or closing.

Energy Release: Controls the precise moment when stored energy is released to move the contacts.

Energy Storage/Buffering: Stores operating energy, typically in springs or capacitors, ready for rapid deployment.

Energy Charging: Recharges the energy storage after each operation, preparing for the next cycle.

Control and Signaling: Interfaces with the control system to receive commands and provide position feedback.

Together, these functions ensure that the circuit breaker can interrupt or restore current flow swiftly and safely.

Circuit breakers employ various operating mechanisms tailored to their application and voltage level:

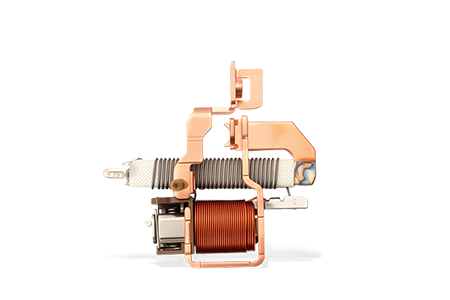

Mechanical Linkage Systems: Traditional designs using levers, cams, and springs. These are common in low-voltage molded case breakers.

Spring Operating Mechanisms: Utilize charged springs to store energy. The energy is released to move the contacts quickly. Widely used for medium and high-voltage breakers.

Motor Drive Mechanisms: Employ electric motors controlled electronically to operate the breaker. This modern approach offers precise control and reduces mechanical wear.

Electromagnetic Mechanisms: Use solenoid coils to actuate the breaker directly, often found in vacuum and SF6 circuit breakers.

Each type offers distinct advantages. For example, spring mechanisms provide rapid operation and are reliable, while motor drives allow for programmable control and condition monitoring.

Energy stored in the operating mechanism is transmitted through mechanical linkages to the breaker contacts. The release is often triggered by a solenoid or latch mechanism activated by trip or close commands. Precision in timing is vital to ensure the contacts open or close at the correct instant to protect the system effectively.

Spring Charging Mechanism: Springs are manually or motor-charged and held in tension until released. This is common in ACB operating mechanisms.

Capacitor Energy Storage: In motor drive systems, capacitors store electrical energy to power the motor during operations.

Hydraulic or Pneumatic Systems: Use fluid pressure to charge and release energy, often found in older or specialized breakers.

The charging method impacts the response time and maintenance requirements.

Modern operating mechanisms integrate sensors and feedback devices that monitor contact position, spring charge status, and mechanism health. This data is communicated to control systems for precise switching and condition monitoring, enhancing reliability and facilitating predictive maintenance.

Operating mechanisms may face issues such as:

Mechanical wear and fatigue in linkages and springs.

Sticking or misalignment of moving parts.

Loss of energy storage capacity.

Electrical faults in motor drives or solenoids.

Environmental factors like temperature and humidity affecting performance.

Regular testing and maintenance are essential to mitigate these challenges.

Recent developments focus on:

Motor Drive Mechanisms: Offering electronic control, fewer moving parts, and enhanced diagnostics.

Adaptive Control Features: Compensate for temperature, voltage variations, and mechanical wear.

Condition Monitoring: Real-time data collection for early fault detection.

Modular Designs: Simplify maintenance and improve reliability.

These innovations aim to increase the lifespan, reduce operational noise, and improve the flexibility of circuit breaker operations.

Tip: Regularly monitor and maintain the spring charging mechanism and control signals of your circuit breaker’s operating mechanism to ensure reliable and precise switching performance.

Circuit breakers rely heavily on their operating mechanisms to protect electrical circuits effectively. These mechanisms ensure the breaker trips promptly during faults and switches reliably during normal operation.

Operating mechanisms integrate two fundamental tripping principles:

Thermal Tripping: Utilizes a bimetallic strip that heats and bends under sustained overcurrent. This bending triggers the trip, opening the breaker contacts. It’s effective for overload protection where current exceeds safe limits for a longer duration.

Magnetic Tripping: Employs an electromagnet coil energized by the fault current. When current surges abruptly, the magnetic force rapidly pulls a latch, causing immediate contact separation. This principle is crucial for short-circuit protection, offering fast response times.

Together, these principles provide comprehensive protection against various fault conditions.

Trip units detect abnormal current conditions and send signals to the operating mechanism. The operating mechanism then translates these signals into mechanical actions that open or close the breaker contacts. This interaction ensures that:

Fault detection is precise and timely.

Mechanical operations occur reliably without delay.

Protection coordination with other devices is maintained.

Modern circuit breaker operating mechanisms often include electronic trip units that enhance sensitivity and allow programmable settings for different protection schemes.

Actuators, commonly solenoid coils, play a pivotal role in initiating breaker operations:

Closing Coil: Energized to close the breaker contacts by releasing the stored energy in the spring charging mechanism.

Tripping Coil(s): Energized to trip the breaker by releasing the latch holding the contacts closed.

These coils convert electrical trip or close commands into mechanical movements. Redundancy is typical, with dual tripping coils ensuring reliability in fault conditions.

Safety and reliability are paramount. To achieve this, operating mechanisms include:

Dual Tripping Coils: Provide backup if one coil fails.

Separate Power Supplies: Each coil is powered independently, often from different DC sources or battery banks.

Auxiliary Contacts: Provide feedback on breaker status to control systems, preventing unintended operations.

Such features minimize the risk of failure and enhance the overall protection system integrity.

After a trip, resetting the breaker prepares it for service again. The design of the operating mechanism influences resetting methods:

Manual Reset: Requires human intervention to charge springs and reset latches.

Motorized Reset: Uses a motor drive to automatically recharge the spring mechanism, enabling remote or automated resetting.

Spring Charged Mechanism: Common in ACB operating mechanisms, where springs store energy and are charged manually or by motor before each operation.

The efficiency and ease of resetting depend on the operating mechanism type, impacting maintenance and operational flexibility.

Tip: Regularly test and maintain tripping coils and their power supplies in your circuit breaker’s operating mechanism to ensure reliable fault detection and swift switching actions.

Achieving precise timing in operating mechanisms is crucial for controlled switching in circuit breakers. Timing accuracy ensures that the breaker opens or closes exactly when intended, minimizing electrical stress and enhancing system reliability.

Operating mechanisms must synchronize their actions with the electrical waveform. Even slight deviations can cause high transient voltages or inrush currents, leading to equipment damage or nuisance tripping. Precise timing reduces these transients, extending the lifespan of the circuit breaker and connected equipment.

Point-on-wave (PoW) switching involves closing or opening the breaker contacts at a specific point on the voltage or current waveform, such as at the zero-crossing or voltage peak. For instance:

Closing at voltage zero-crossing reduces inrush current when energizing capacitive loads.

Closing at voltage peak can minimize transient overvoltages when switching inductive loads.

This technique significantly lowers switching transients and enhances power quality.

Operating mechanisms face variations due to temperature changes, control voltage fluctuations, mechanical wear, and idle time between operations. Adaptive control systems monitor these factors and adjust timing commands accordingly, ensuring consistent performance despite changing conditions.

Proper commissioning involves measuring the circuit breaker's operating times under actual site conditions. Periodic testing verifies that the operating mechanism maintains its timing accuracy and functionality over time. These practices help detect wear or drift early, preventing unexpected failures.

Shunt Reactor Switching: Controlled switching at voltage peaks reduced current asymmetry and prevented relay misoperations.

Transformer Energization: Synchronizing breaker closing with residual flux minimization lowered inrush currents, protecting transformer integrity.

Capacitor Bank Switching: PoW control eliminated harmful voltage surges, extending equipment lifespan.

These examples highlight how precise operating mechanism synchronization leads to improved system reliability and reduced maintenance costs.

Tip: Regularly calibrate and adapt your circuit breaker’s operating mechanism timing to compensate for environmental and mechanical changes, ensuring optimal controlled switching performance and minimizing transient stresses.

Circuit breaker operating mechanisms have evolved significantly, moving from traditional mechanical designs to advanced motor drive systems. Understanding these differences helps in selecting the right mechanism for specific applications.

Conventional operating mechanisms rely heavily on mechanical components such as springs, levers, and linkages. While proven and reliable, they present several challenges:

Complexity and Wear: Multiple moving parts increase the risk of mechanical wear and fatigue, leading to potential failures over time.

Impact Operation: Mechanical impacts during switching cause noise and vibration, which can accelerate component degradation.

High Auxiliary Power Demand: Charging springs or operating hydraulic systems often require high transient power, stressing auxiliary supplies.

Limited Condition Monitoring: Mechanical systems offer minimal real-time diagnostic capabilities, making predictive maintenance difficult.

Fixed Performance: Mechanical linkages are dimensionally fixed, limiting adaptability to different breaker models or changing operational requirements.

Modern motor drive operating mechanisms introduce electronic control combined with a single moving part—an electric motor. This design offers several advantages:

Simplified Design: With only one moving part, motor drives reduce mechanical complexity and wear.

Reduced Noise and Vibration: The motor provides smooth motion, eliminating harsh mechanical impacts.

Lower Power Consumption: Energy is stored in capacitors and delivered efficiently, minimizing peak auxiliary power demands.

Advanced Condition Monitoring: Integrated sensors track motor position, current, and energy buffer status, enabling predictive maintenance.

Programmable Control: Electronic control allows precise adjustment of operating speed and travel curves to match specific breaker requirements.

Enhanced Reliability: Fewer mechanical parts and continuous monitoring improve overall system dependability.

Motor drive mechanisms drastically reduce maintenance needs. The absence of complex mechanical linkages means less lubrication, fewer replacements, and simpler inspections. Additionally, quieter operation improves substation environments and reduces mechanical stress on foundations.

Modern designs incorporate real-time diagnostics, including:

Monitoring contact travel and motor torque.

Tracking energy buffer charge levels.

Detecting deviations from programmed travel curves.

Alerting operators to potential faults before failures occur.

These features facilitate proactive maintenance, reducing downtime and extending breaker lifespan.

Motor drives can be adapted to various circuit breaker types, including ACB operating mechanisms and SF6 circuit breaker mechanisms. Their programmable nature supports customization for different voltage levels and switching speeds. This scalability makes them suitable for a wide range of applications, from medium-voltage rotary operating mechanisms to high-voltage breakers.

Tip: Consider upgrading to motor drive operating mechanisms for improved reliability, reduced maintenance, and enhanced monitoring capabilities in your circuit breaker installations.

The operating mechanism of a circuit breaker is a finely tuned system made up of several key components, each playing a vital role in ensuring reliable and rapid switching. Let's explore these components and understand how they contribute to the circuit breaker’s operation.

Mechanical linkages form the physical connection between the operating mechanism and the breaker contacts. These linkages translate stored energy into movement, allowing the contacts to open or close swiftly. The design includes levers, cams, and rods engineered for precision and durability. Proper alignment and lubrication are essential to prevent sticking or misoperation, which can cause failure in the breaker operating mechanism.

Spring systems are commonly used to store the energy required to operate the breaker contacts. The breaker spring charging mechanism involves compressing or tensioning springs, which hold potential energy until released. Upon a trip or close command, this stored energy is discharged rapidly to move the contacts. There are typically two springs: one for closing and another for opening the contacts. The spring charged mechanism of circuit breaker ensures fast operation and consistent performance. Charging can be manual or motorized, especially in ACB operating mechanisms, where motorized charging improves ease of use.

Modern operating mechanisms integrate sensors that provide real-time feedback on the position and status of the breaker contacts and springs. These sensors monitor whether the contacts are open, closed, or in transition, and whether the springs are fully charged. This information is crucial for control systems to verify correct operation and to enable condition monitoring, helping to predict maintenance needs before failures occur.

Auxiliary contacts serve as electrical signals within the control circuit, indicating the status of the main contacts. They provide feedback to supervisory control and protection systems, confirming whether a breaker is open or closed. These contacts are vital for interlocking schemes, preventing unsafe operations, and coordinating with other protective devices.

The operating mechanism works closely with trip coils and closing coils, which are solenoid coils energized to initiate breaker operations. When a fault is detected, the trip coil energizes, releasing the spring latch and opening the contacts. Conversely, the closing coil energizes to release the closing spring, allowing the contacts to close. Redundancy in trip coils and separate power supplies enhance reliability and safety, ensuring the breaker operates correctly even if one coil fails.

Tip: Regularly inspect and maintain the spring charging mechanism and auxiliary contacts in your circuit breaker’s operating mechanism to ensure swift, reliable switching and accurate status feedback.

Designing operating mechanisms for circuit breakers demands careful consideration to guarantee reliability and safety, especially across high-voltage and medium-voltage applications. These mechanisms must withstand harsh operating conditions while delivering consistent performance.

High-voltage circuit breakers require operating mechanisms capable of handling significant mechanical forces and rapid switching actions. Designers focus on:

Robustness: Components must endure heavy mechanical stresses and electrical arcs.

Precision: Accurate timing ensures protective coordination and controlled switching.

Environmental Resistance: Mechanisms should function reliably amid temperature extremes, humidity, and contaminants.

Medium-voltage breakers, such as those with ACB operating mechanisms or rotary operating mechanisms, balance compactness with durability to fit diverse installation needs.

Materials used in operating mechanisms significantly impact longevity and reliability. Key factors include:

Wear Resistance: Springs, linkages, and contacts often use hardened steel or specialized alloys to minimize fatigue.

Corrosion Resistance: Protective coatings or stainless materials prevent degradation in moist or polluted environments.

Low Friction: Lubricants and smooth surfaces reduce wear and sticking, critical in breaker spring charging mechanisms and spring charged mechanisms of circuit breakers.

Mechanical impacts during switching can cause noise and accelerate wear. To mitigate this:

Dampers and Shock Absorbers: Installed to soften mechanical impacts.

Optimized Linkage Design: Reduces unnecessary movement and stress.

Motor Drive Mechanisms: Offer smoother operations with less vibration compared to traditional spring or pneumatic systems.

These improvements help extend the life of the circuit breaker operating mechanism and reduce maintenance frequency.

Safety-critical applications demand fail-safe designs:

Dual Trip Coils: Provide redundancy in tripping to ensure breaker operation even if one coil fails.

Mechanical Latches and Locks: Prevent unintended operations and ensure the breaker remains in a safe state during faults.

Spring Charging Monitoring: Sensors verify that springs are properly charged, preventing incomplete switching actions.

Such features are vital in SF6 circuit breaker mechanisms and other high-reliability breakers.

Compliance with international standards like IEC 62271 and ANSI C37 ensures:

Performance Validation: Operating times, mechanical endurance, and electrical characteristics meet stringent criteria.

Safety Assurance: Mechanisms function correctly under fault and environmental stress.

Quality Control: Manufacturing processes produce consistent, reliable components.

Regular testing, including mechanical endurance and environmental stress tests, helps maintain high reliability.

Tip: Implement routine inspections focusing on spring condition, linkage wear, and actuator performance in your circuit breaker’s operating mechanism to prevent unexpected failures and ensure safe, reliable switching operations.

Operating mechanisms are vital for fast, reliable circuit breaker switching and system protection. Advances like motor drives and adaptive controls enhance precision and reduce wear. Regular maintenance and monitoring improve performance and prevent failures. Selecting the right mechanism depends on voltage level, application, and desired control features. HAIPART offers innovative operating mechanisms that deliver durability, advanced diagnostics, and efficient operation, ensuring optimal protection and longevity for electrical systems. Trust HAIPART for reliable, cutting-edge circuit breaker solutions.

A: The operating mechanism is the heart of circuit breaker switching, responsible for storing and releasing energy to open or close breaker contacts swiftly and reliably. It translates control commands into mechanical actions, ensuring precise and safe interruption or restoration of current flow.

A: Common types include mechanical linkage systems, spring operating mechanisms like the breaker spring charging mechanism, motor drive mechanisms, and electromagnetic mechanisms such as those used in SF6 circuit breaker mechanisms. Each type suits different voltage levels and applications.

A: The spring charged mechanism stores energy in springs, which are manually or motor-charged. Upon a trip or close command, this stored energy is rapidly released to move the contacts, enabling fast and reliable switching, commonly seen in ACB operating mechanisms.

A: Precise timing in the operating mechanism minimizes switching transients and electrical stress by synchronizing contact movement with the electrical waveform, improving system reliability and reducing equipment wear. Adaptive controls help maintain this accuracy despite environmental or mechanical variations.

A: Motor drive mechanisms reduce mechanical wear with fewer moving parts, lower noise and vibration, enable programmable control, and provide advanced condition monitoring. This enhances reliability, reduces maintenance, and improves flexibility across diverse circuit breaker applications.

A: Regular inspection and maintenance of the spring charging mechanism, mechanical linkages, trip and close coils, and auxiliary contacts are essential. Monitoring sensors and performing periodic testing help detect wear or faults early, ensuring safe and dependable circuit breaker switching.

The closing mechanism releases stored energy—usually in a spring charging system—to drive the contacts into the closed position. When a close command is given, the closing coil or latch activates, allowing the stored spring energy to snap the contacts shut quickly and securely.

A circuit breaker switches by converting stored mechanical energy into contact movement. A trip signal releases the latch, causing stored opening energy to separate the contacts, interrupting current flow. A close signal releases the closing spring to re-engage the contacts. Trip units, coils, and mechanical linkages coordinate these actions.

The operating mechanism is the core system responsible for storing, controlling, and releasing the energy required to open or close breaker contacts. It includes components such as springs, linkages, latches, trip coils, closing coils, and motor charging units. It ensures fast, reliable switching during both normal operation and fault conditions.

The latching mechanism holds the breaker contacts in the closed position. When a trip signal is received—thermal, magnetic, or electronic—the latch is released, allowing the stored opening energy to rapidly separate the contacts. The latch must be reset manually or automatically before the breaker can close again.

A circuit closes when conductive contacts physically touch, allowing current to flow. It opens when the contacts separate, interrupting the current path. In circuit breakers, this action is aided by springs, linkages, and a tripping mechanism that ensures fast and controlled opening during faults.

A circuit breaker works by detecting abnormal current conditions and using an operating mechanism to open its contacts. Thermal or magnetic trip units sense overloads or short circuits and trigger the operating mechanism to release stored energy, rapidly separating the contacts to interrupt current flow.

The spring mechanism stores mechanical energy required for opening and closing operations. Closing springs drive the contacts into the closed position, while opening springs ensure rapid contact separation during tripping. Springs may be charged manually or by a motor in modern operating mechanisms.

A breaker closes when the closing coil or manual toggle releases the closing spring. This stored energy drives the mechanical linkages that push the contacts together. In motor-operated systems, the spring automatically recharges after closing.

A closed circuit provides a continuous, unbroken path for current to flow from source to load and back. When a circuit breaker is closed, its contacts connect the conductive path, enabling current flow. When it opens, the path is broken, stopping current immediately.