Views: 0 Author: Site Editor Publish Time: 2025-11-17 Origin: Site

Ever wondered what keeps your electrical circuits safe from damage? Circuit breakers like MCBs play a vital role.

MCBs and MCCBs differ in capacity and use, but both protect your home and industry.

In this post, you’ll learn about their key internal components and why understanding them ensures safety and proper maintenance.

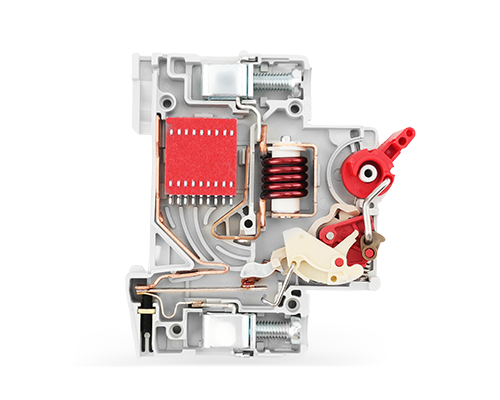

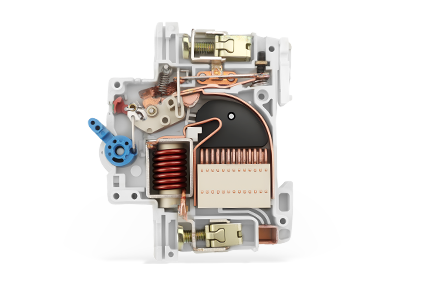

Understanding the mcb components inside and the mccb components list is essential for grasping how these devices protect electrical circuits. Both MCBs (Miniature Circuit Breakers) and MCCBs (Molded Case Circuit Breakers) share several internal parts, though their design and capacity differ. Let’s explore the key parts of mcb and MCCB that make them reliable safety devices.

The outer shell of both MCBs and MCCBs is a molded insulation housing, typically made from high-strength thermosetting plastics. This housing:

Protects internal components from dust, moisture, and mechanical damage

Provides electrical insulation to prevent accidental contact with live parts

Acts as a flame-retardant barrier during arc interruption

This robust casing ensures safety and durability in various environments.

The operating mechanism connects the external switch or toggle to the internal contacts. It allows:

Manual switching ON/OFF of the circuit breaker

Rapid opening of the circuit in fault conditions via a spring-loaded mechanism

Resetting the breaker after a trip

This mechanism often includes levers, springs, and latches that work together to ensure fast and reliable contact separation.

The trip unit is the heart of the mcb internal mechanism and mccb internal structure. It senses abnormal current and triggers the breaker to trip. It consists of:

Thermal Trip: A bimetallic strip that bends when heated by prolonged overload current, causing a delayed trip.

Magnetic Trip: An electromagnet that instantly trips the breaker during short circuits by pulling a plunger to release the latch.

Some MCCBs also use electronic trip units for precise control and adjustable settings.

The main contacts carry the load current under normal operation. They include:

Fixed Contacts: Stationary and connected to the supply or load terminals.

Movable Contacts: Linked to the operating mechanism and separate during tripping.

These contacts are made of copper or silver alloys to ensure excellent conductivity and resistance to arc erosion.

When contacts open under load, an electric arc forms. The arc chute, composed of insulated metal plates, serves to:

Split the arc into smaller segments

Cool and extinguish the arc rapidly

Protect the breaker from damage and prevent fire hazards

This arc quenching system is vital for safe interruption of current.

Terminals provide secure connection points for incoming and outgoing wires. Depending on the design, they may be:

Screw-type for smaller MCBs

Bolt-on or plug-in for MCCBs and larger breakers

High-conductivity materials like copper are used to minimize resistance and ensure reliable current flow.

Modern MCBs and MCCBs can include additional components such as:

Auxiliary contacts for signaling breaker status

Shunt trip units for remote tripping

Undervoltage releases to trip during low voltage conditions

These accessories add flexibility and improve system integration.

Tip: Regular inspection of the mcb circuit breaker parts like contacts and trip units ensures reliable operation and prevents unexpected failures in your electrical systems.

Trip mechanisms are vital mcb working components that ensure electrical safety by interrupting current during faults. Both MCBs and MCCBs use trip units designed to detect abnormal current and trigger the breaker to open. Let’s explore the main types of trip mechanisms and how they function inside these circuit breakers.

The thermal trip unit uses a bimetallic strip, made of two metals with different expansion rates bonded together. When current flows normally, the strip remains straight. However, during an overload, excess current heats the strip. Because the metals expand differently, the strip bends as it warms.

This bending action slowly moves a latch, releasing the operating mechanism to open the circuit breaker contacts. Thermal trips provide time-delayed protection, allowing brief surges like motor starts without nuisance tripping. The higher the overload current, the faster the strip bends and trips the breaker.

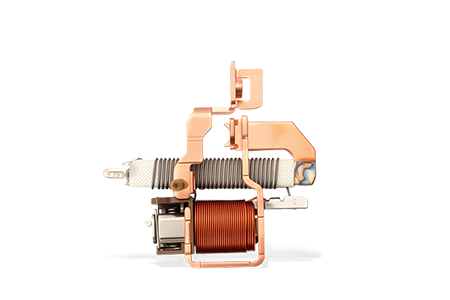

For sudden, large fault currents such as short circuits, the magnetic trip unit acts instantly. It contains a coil or solenoid energized by the load current. Under normal conditions, the magnetic force is too weak to act.

But when a high fault current flows, the magnetic field rapidly increases and pulls a plunger or armature. This mechanical action immediately releases the latch, causing the breaker to trip without delay. The magnetic trip provides instantaneous protection, preventing damage from high fault currents.

Some MCCBs incorporate electronic trip units that use sensors and microprocessors to monitor current precisely. These units can differentiate between overloads, short circuits, and ground faults with programmable settings.

Electronic trips offer adjustable thresholds and time delays, enabling tailored protection for complex systems. They also allow communication with monitoring equipment, enhancing fault diagnostics and system coordination.

Most MCBs and MCCBs use a combined thermal-magnetic trip unit. This hybrid design offers robust protection against both prolonged overloads and instantaneous short circuits. The thermal part handles overloads with a time delay, while the magnetic part trips immediately on severe faults.

This combination ensures comprehensive protection, balancing sensitivity and reliability in various electrical environments.

After a trip event, the breaker must be manually reset. The operating mechanism allows the user to switch the breaker back ON once the fault is cleared. This reset restores the contacts to the closed position, ready for normal operation.

The trip mechanism’s design ensures it cannot be bypassed during a fault, maintaining safety. Manual reset also serves as a checkpoint, prompting inspection before restoring power.

Tip: Regularly testing the trip mechanisms in your MCB or MCCB helps ensure reliable protection and prevents unexpected failures in your electrical system.

Understanding the materials and design considerations of MCB breaker components and MCCB internal structure is crucial for ensuring durability, performance, and safety. Both devices rely on carefully selected materials to withstand electrical, thermal, and mechanical stresses while maintaining reliable operation.

The outer casing of both MCBs and MCCBs is typically made from thermosetting plastics such as:

Dough Molding Compound (DMC)

Melamine

Epoxy resin

These materials offer excellent electrical insulation, mechanical strength, and heat resistance. They protect the internal parts from environmental factors like moisture, dust, and impact. Additionally, the housing is designed to be flame-retardant, preventing fire propagation during arc events inside the breaker.

The main contacts inside MCBs and MCCBs are responsible for carrying load currents and must resist wear from electrical arcing. Common materials include:

Copper alloys: Provide good electrical conductivity and mechanical strength.

Silver alloys (such as silver-cadmium oxide): Enhance conductivity and offer superior resistance to arc erosion.

These materials ensure low contact resistance and longer service life. The choice of alloy balances conductivity, durability, and cost.

The arc chute, a critical component for safely interrupting arcs formed during contact separation, is constructed from ferromagnetic steel plates. These plates are:

Insulated from each other to create multiple arc segments.

Arranged in stacks or grids to cool and split the arc rapidly.

Designed to lengthen the arc path, reducing its energy and extinguishing it safely.

This design minimizes damage to the breaker and reduces fire hazards.

Terminals connect the circuit breaker to external wiring. They are usually made from:

Copper or copper alloys for excellent electrical conductivity.

Often tin- or silver-plated to prevent oxidation and ensure reliable connections.

Terminals are designed to accept various types of connectors, such as screw terminals for smaller MCBs or bolt-on connections for MCCBs. Safety covers often protect terminals from accidental contact.

Tip: Selecting circuit breakers with high-quality materials in their mcb internal parts and mccb breaker parts enhances longevity and reduces maintenance needs, ensuring safer electrical installations.

When selecting an MCB or MCCB, understanding their types and classifications based on internal components is crucial. These classifications influence how the breakers respond to faults and suit different applications.

Most traditional MCBs and MCCBs use thermal-magnetic trip units. The thermal part employs a bimetallic strip that bends with heat from prolonged overloads, while the magnetic part uses an electromagnet for instantaneous short-circuit detection. This combination offers reliable dual protection.

On the other hand, electronic trip units use sensors and microprocessors to monitor current precisely. They allow adjustable trip settings, enhanced fault discrimination, and communication capabilities. Electronic MCCBs are common in complex industrial systems requiring fine-tuned protection.

| Trip Unit Type | Description | Typical Use Cases |

|---|---|---|

| Thermal-Magnetic | Mechanical bimetallic strip + electromagnet for trips | Residential and general industrial |

| Electronic | Microprocessor-controlled, adjustable settings | Critical industrial and data centers |

Fixed trip breakers have preset trip points determined by the manufacturer. They are simple and cost-effective, suitable for standard circuits where loads are predictable.

Adjustable trip breakers, mainly MCCBs, allow users to set overload and short-circuit trip thresholds. This flexibility helps coordinate protection in complex systems and prevents nuisance tripping, especially in industrial environments.

Magnetic-Only Breakers: These trip instantly on short circuits but do not protect against overloads. They are often used in motor circuits where separate overload relays provide thermal protection.

Thermal-Only Breakers: These respond only to overloads, with no instantaneous short-circuit trip. They are less common and typically found in specialized applications.

Hybrid Breakers: Combine features of thermal, magnetic, and sometimes electronic trip units, providing tailored protection.

MCBs are classified by their tripping curves, which define how quickly they trip at different overcurrent levels:

| MCB Type | Trip Current Range (times rated current) | Typical Applications |

|---|---|---|

| Type B | 3 to 5 times | Residential lighting and heating |

| Type C | 5 to 10 times | Commercial and small motor loads |

| Type D | 10 to 20 times | Large motors and transformers |

| Type K | 8 to 12 times | Motor loads with high inrush currents |

| Type Z | 2 to 3 times | Sensitive electronics |

Choosing the right type ensures the breaker trips appropriately, avoiding nuisance trips while protecting equipment.

Tip: When selecting an MCB or MCCB, consider the trip unit type and adjustability to match your system’s load characteristics and fault current levels for optimal protection and reliability.

Selecting the right MCB or MCCB components inside an electrical system is crucial for ensuring safety, efficiency, and reliability. The choice depends on several factors, including current and voltage ratings, breaking capacity, application environment, and maintenance needs. Understanding these criteria helps engineers and electricians make informed decisions.

The current rating is the maximum continuous current the breaker can safely carry without tripping. For MCB circuit breaker parts, typical ratings range from 0.5A to 63A, making them ideal for residential and light commercial applications. In contrast, MCCB components list includes breakers rated from 15A up to 2500A or more, suitable for industrial and large commercial setups.

Voltage rating must match or exceed the system voltage to prevent insulation breakdown or premature failure. For example, MCBs often handle voltages up to 240V AC, while MCCBs can be rated for voltages up to 690V AC or higher.

Breaking capacity, or interrupting rating, defines the maximum fault current the breaker can safely interrupt. This is a critical safety parameter. MCBs generally have breaking capacities up to 10kA, sufficient for smaller circuits. MCCBs offer much higher breaking capacities, sometimes exceeding 100kA, to handle severe fault conditions in industrial environments.

Compliance with international standards like IEC 60898 for MCBs and IEC 60947-2 for MCCBs ensures the components meet rigorous safety and performance requirements. Selecting breakers certified to these standards guarantees reliable operation under fault conditions.

In residential settings, key parts of MCB like fixed trip settings and compact size make them practical and cost-effective. They protect lighting circuits, heating systems, and small appliances.

Industrial applications demand more robust MCCB internal parts with adjustable trip settings to accommodate varying load conditions and motor starting currents. Features such as shunt trips, undervoltage releases, and auxiliary contacts enhance control and monitoring capabilities in complex systems.

Routine inspection of MCB breaker components and MCCB breaker parts is vital. Checking for contact wear, corrosion, or mechanical failures in the operating mechanism helps prevent unexpected trips or failures. Testing trip units ensures they respond correctly to overload and short-circuit conditions.

Troubleshooting may involve verifying terminal connections, cleaning arc chutes, or replacing worn bimetallic strips. Understanding the mcb internal mechanism and mccb internal structure aids in diagnosing faults quickly and accurately.

Tip: Always match the MCB or MCCB’s current rating and breaking capacity to your system’s requirements and ensure compliance with relevant safety standards for optimal protection and longevity.

Grasping the mcb internal parts and mccb internal structure is more than just technical knowledge—it directly impacts safety, maintenance, and performance. Knowing the key parts of mcb and components of mccb breaker inside helps professionals ensure systems function reliably and safely.

Understanding the mcb circuit breaker parts and mccb breaker parts allows electricians to install devices correctly, ensuring that:

Contacts align properly to avoid overheating

Trip units respond accurately to faults

Arc chutes effectively extinguish arcs

Proper maintenance, guided by knowledge of the mcb internal mechanism and mccb internal structure, prevents failures that could lead to electrical fires or equipment damage.

When an MCB or MCCB trips unexpectedly, familiarity with its internal parts and functions enables quicker fault identification. For example:

Inspecting the bimetallic strip for deformation in thermal trips

Checking the solenoid coil in magnetic trip units

Examining arc chutes for damage or carbon deposits

This insight reduces downtime by pinpointing issues without guesswork.

Selecting the right mcb parts explained and understanding their operation ensures that circuit breakers perform as intended. For instance:

Choosing MCBs with appropriate trip curves (Type B, C, or D) based on load characteristics

Utilizing MCCBs with adjustable trip settings for tailored protection

Incorporating optional accessories like shunt trips or auxiliary contacts to enhance system control

Such optimization helps balance sensitivity and nuisance tripping.

Knowledge of internal components supports compliance with standards like IEC 60898 for MCBs and IEC 60947-2 for MCCBs. Professionals can verify that:

Materials meet insulation and conductivity requirements

Trip mechanisms conform to safety and performance norms

Accessories are compatible and certified

Compliance not only meets legal requirements but also guarantees reliable protection.

Tip: Regularly reviewing the mcb internal diagram and mccb components list during installation and maintenance boosts safety and extends the lifespan of your electrical protection devices.

Understanding the key components inside MCBs and MCCBs is essential for electrical safety. Critical parts like trip units, contacts, and arc chutes ensure reliable circuit protection. High-quality materials and precise design improve breaker durability and performance. Professionals should carefully select and maintain breakers to match system needs and prevent failures. HAIPART offers reliable circuit breakers with superior internal components, enhancing safety and longevity in electrical installations. Trust HAIPART for dependable protection and expert service.

A: The key parts of an MCB include the molded insulation housing, operating mechanism, trip unit (thermal and magnetic), main contacts, arc chute, and terminal connectors. These components work together to detect faults, interrupt current flow, and protect electrical circuits effectively.

A: The MCB internal mechanism uses a combined thermal-magnetic trip unit. The thermal trip employs a bimetallic strip that bends during overloads, while the magnetic trip instantly reacts to short circuits by releasing a latch to open the contacts, ensuring fast and reliable protection.

A: MCCB components list includes a molded insulation housing, an operating mechanism, thermal-magnetic or electronic trip units, main contacts, arc chute, terminal connectors, and optional accessories like auxiliary contacts and shunt trips for enhanced functionality.

A: Knowing MCB circuit breaker parts helps in inspecting contacts, trip units, and arc chutes to prevent failures. It aids in troubleshooting by identifying worn bimetallic strips or faulty magnetic coils, ensuring reliable operation and safety.

A: MCB parts explained focus on smaller, fixed-trip units suited for low current ratings, while MCCB internal structure includes larger, often adjustable trip units, higher breaking capacities, and advanced electronic options for industrial applications.

A: MCB breaker components use thermosetting plastics for housing, copper or silver alloys for contacts, and ferromagnetic plates in arc chutes. These materials ensure electrical insulation, conductivity, durability, and effective arc interruption.

A: Both use thermal-magnetic trip units, but MCCBs may also have electronic trip units with adjustable settings for precise fault detection, while MCBs typically have fixed thermal-magnetic trips suitable for residential or light commercial use.

A Molded Case Circuit Breaker (MCCB) contains several key components:

Molded insulation housing

Operating mechanism

Thermal overload trip unit

Magnetic instantaneous trip unit

Optional electronic trip unit

Fixed and moving contacts

Arc chute assembly

Terminal connectors

Optional accessories such as shunt trip, undervoltage release, and auxiliary contacts

These components work together to provide adjustable and high-capacity protection for industrial and commercial power circuits.

A Miniature Circuit Breaker (MCB) includes:

Thermoset molded housing

Toggle and spring-loaded operating mechanism

Thermal bimetal trip element

Magnetic solenoid trip

Fixed and moving contacts

Arc chute made of layered metal plates

Terminal connectors

MCBs use thermal-magnetic tripping to protect low-voltage circuits.

All circuit breakers—MCB, MCCB, ACB, etc.—share these essential components:

Contacts (fixed & movable)

Arc-extinguishing system (arc chute)

Operating mechanism

Trip unit (thermal, magnetic, or electronic)

Insulated molded housing

Terminals for wiring connections

These components allow safe interruption of fault currents.

The internal structure of a breaker consists of:

An insulated molded case

Mechanism system (toggle, springs, latch)

Trip mechanism (thermal, magnetic, or electronic sensing)

Main conductive path with fixed and moving contacts

Arc chute with metallic arc-splitting plates

Terminals for line and load connections

Together, these ensure controlled switching and safe interruption under fault conditions.

A breaker generally includes:

Main contacts

Arc chute

Operating mechanism

Trip mechanism

Molded insulation case

Terminal blocks

This structure is common across most low-voltage protective breakers.

MCB (Miniature Circuit Breaker):

A compact, fixed-trip thermal-magnetic breaker rated typically up to 63A.

MCCB (Molded Case Circuit Breaker):

A larger, higher-capacity breaker rated up to 2500A with adjustable or electronic trip units.

Both protect circuits from overloads and short circuits but serve different power levels.

An MCB is a miniature circuit breaker designed for low-voltage circuits. It uses:

A thermal bimetal strip for overloads

A magnetic solenoid for short circuits

MCBs are widely used in residential and light commercial electrical systems.

The main purpose of an MCCB is to provide:

High-capacity short-circuit protection

Adjustable overload protection

Optional ground-fault and long-delay protection (with electronic trip units)

MCCBs are essential for industrial and commercial power distribution systems.

MCB: Thermal-magnetic breaker for low-current circuits

MCCB: Adjustable, high-current molded case breaker

ELCB/RCCB: A residual-current device that protects against earth leakage faults

They serve different protection functions in electrical systems.

A basic electrical circuit consists of:

Power source

Conductors (wiring)

Load (device consuming power)

Control/switch element

These allow current to flow and be controlled.

The five essential components are:

Power supply

Conductors

Load

Switch or control device

Protection device (fuse or circuit breaker)

Same as above:

Source

Conductors

Load

Switch

A power system typically includes:

Generation

Step-up transformers

Transmission network

Step-down transformers

Distribution network

End-use loads

Common basic components include: resistor, capacitor, inductor, diode, LED, transistor, relay, switch, fuse, circuit breaker, transformer, connector, power supply, and ground/reference point.

The four major components are:

Generation

Transmission

Distribution

Utilization (loads)

The main electricity sources include:

Coal

Natural gas

Nuclear energy

Hydropower

Wind energy

Solar energy

A breaker panel typically contains:

Main breaker

Busbars (hot, neutral, ground)

Branch circuit breakers

Neutral bar

Grounding bar

Enclosure

In many contexts, Type 3 refers to:

Type C MCB, which trips at 5–10 times the rated current, suitable for inductive loads with moderate inrush currents.

In wiring diagrams, an MCB symbol represents an overcurrent protection device that interrupts overload and short-circuit faults.

Typical panel components include:

Main disconnect

Busbars

Branch circuit breakers

Relays/contactors

Meters and indicators

Terminal blocks

Grounding system

Key basics include:

Thermal-magnetic or electronic trip units

Adjustable overload and short-circuit settings

High breaking capacity

Molded case construction

Wide current range up to thousands of amperes

Air Circuit Breakers (ACB) generally include:

Arc chute

Main contacts

Spring/operating mechanism

Electronic trip unit