Views: 0 Author: Site Editor Publish Time: 2025-08-04 Origin: Site

Selecting the right circuit breaker is very important. It can change how electrical systems work. Molded case circuit breakers are used a lot in factories and big buildings. They give strong protection and work with many current levels. Around the world, molded case circuit breakers make up over 65% of circuit breaker sales. They are growing fast in power and building projects.

Aspect | Statistic / Insight |

|---|---|

MCCB Market Revenue Share | |

Dominant Usage | Preferred in industrial and commercial sectors for reliable power protection |

Market Growth Drivers | Expansion of power networks, renewables, and smart grids |

Choosing the right circuit breaker keeps people safe. It also helps stop power loss and saves money. New electrical protection devices have better features. They help stop accidents and keep things working well in tough places.

MCCBs keep electrical systems safe by stopping too much current and short circuits. They have settings you can change for different power needs. They are very strong and last a long time. They work well in hard places like factories, big buildings, and places with solar or wind power. MCCBs can handle more power than other breakers. They give more ways to protect the system. They also last longer and need less fixing. You need to pick the right breaker for the power, place, and safety you need. MCCBs are best for big and tricky systems. Checking breakers often and picking the right one keeps people safe. It also stops damage and makes sure power works well everywhere.

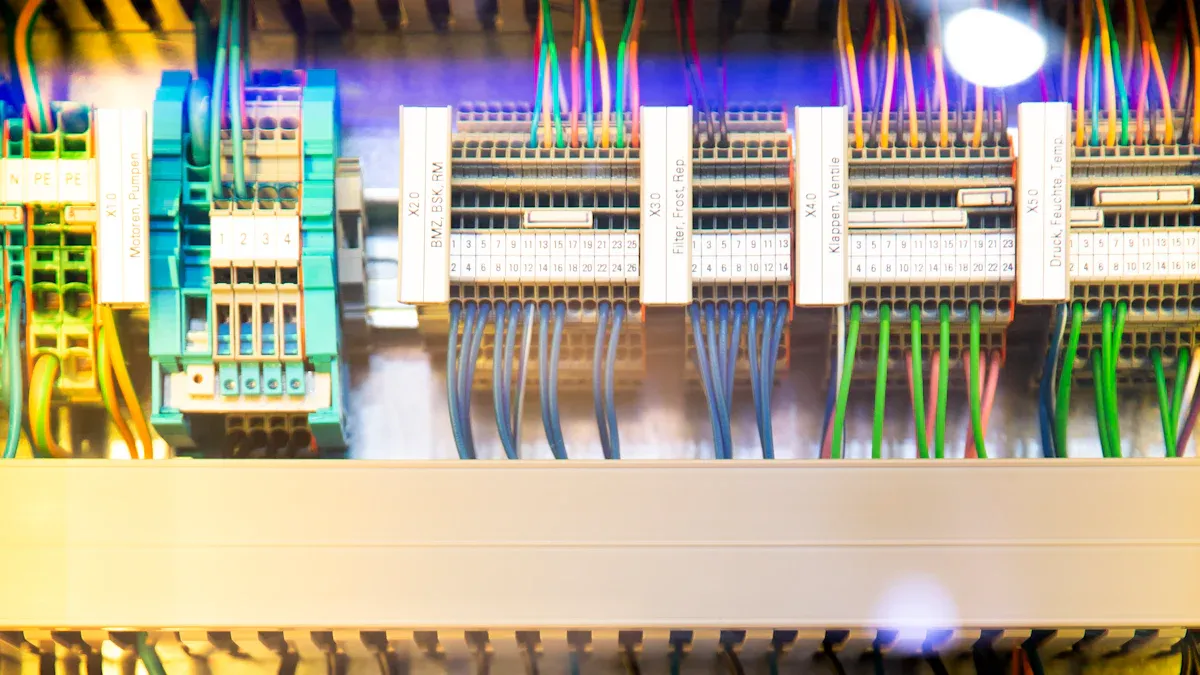

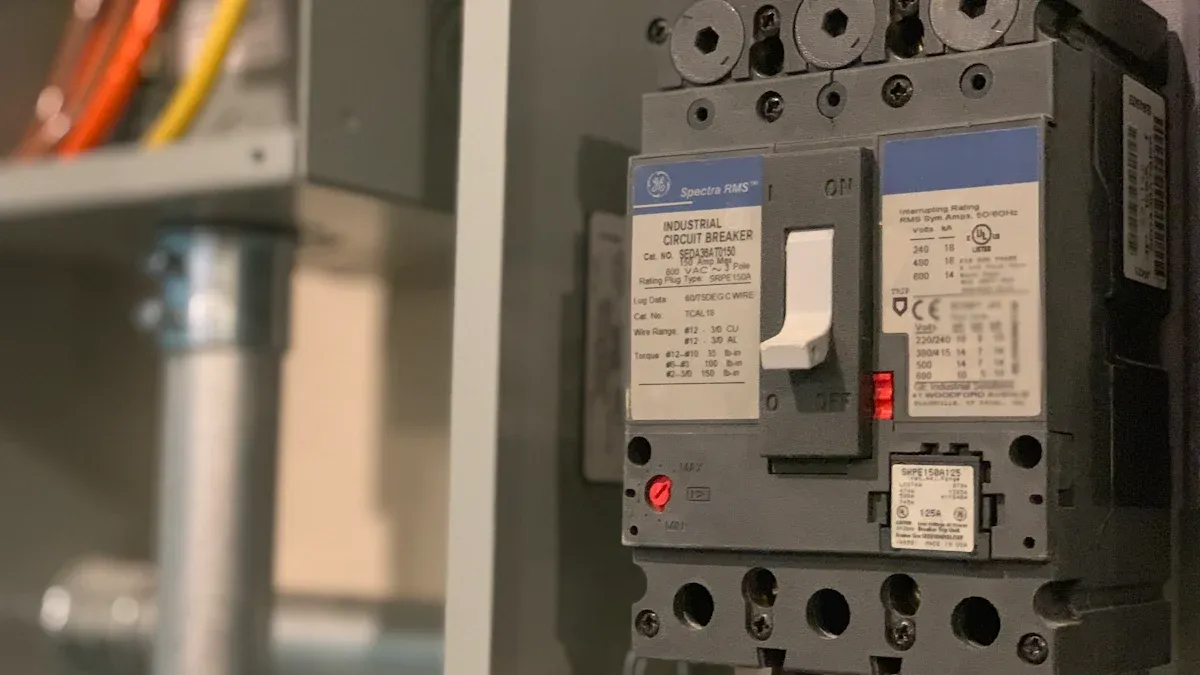

A molded case circuit breaker, called an MCCB, helps protect electrical systems from getting damaged by too much current or short circuits. It has a hard, nonconductive case that keeps its parts safe and cool. This makes the MCCB last longer and work better. MCCBs can handle many different current levels, so they fit many uses. HAIPART is a brand that makes strong MCCBs for factories and big buildings. Their MCCBs can stop high currents and follow safety rules from around the world.

MCCBs keep people and equipment safe by turning off power if they find a dangerous problem in the circuit.

MCCBs are different from other breakers because they have special features. They use both thermal and magnetic trip units to give two kinds of protection. This helps stop damage from too much current or short circuits. You can change the trip settings on an MCCB. This means you can use it for small or large currents. MCCBs can also stop very high fault currents without breaking.

Characteristic / Specification | Description |

|---|---|

Main Components | Molded case, terminals, switch handle, trip unit, arc chamber |

Rated Current (In) | Adjustable overload protection threshold |

Rated Frame Current (Inm) | Maximum current capacity based on size |

Rated Insulation Voltage (Ui) | Maximum voltage the MCCB can withstand |

Rated Working Voltage (Ue) | Continuous operating voltage |

Interrupting Capacity (Ics) | Maximum fault current the MCCB can interrupt and still be reused |

Mechanical/Electrical Life | Number of operations before failure |

Adjustable Trip Settings | Allows use in various current applications |

MCCBs also have trip indicators and current limiting features. These give extra safety and help protect circuits even more.

MCCBs are used in many places because they are flexible and reliable. They protect motors, welding machines, generators, and capacitor banks in factories. In big buildings, MCCBs are the main breaker in power boards. Solar farms and other renewable energy systems use MCCBs to keep solar panels safe from faults. Their strong build and adjustable settings make them good for tough jobs.

MCCBs protect heavy machines from too much current.

They work well in places with dust or moisture because they are built strong.

MCCBs help keep factories, data centers, and ships safe and running smoothly.

HAIPART MCCBs follow world standards and give a safe way to control important power systems.

Miniature circuit breakers protect small electrical systems in homes and offices. They are small and use a thermal or thermal-magnetic trip. Most MCBs have trip settings that cannot be changed. Electricians like MCBs because they are easy to put in and not expensive. The IEC 60898-1 standard says how to use them in homes and similar places. MCBs work with currents up to 125A. They help stop overloads and short circuits in daily circuits.

Air circuit breakers, called ACBs, are used in big factories and power stations. These breakers can handle large amounts of current. They use air to put out the arc when breaking a circuit. ACBs have trip settings that can be changed by trained workers. This helps protect big machines and power lines. Their design makes them easy to fix and use with new control systems. Factories, data centers, and power stations use ACBs for main power protection. ACBs follow IEC 60947-2 rules and work with voltages up to 1000V.

Tip: ACBs are good for backup power and big generators because they can handle strong starting currents.

Insulated case circuit breakers are used in big factories that need more power than MCCBs give. ICCBs have a plastic frame with no metal, which makes them safer. These breakers use a two-step stored energy system to work well. ICCBs protect like MCCBs but have a stronger build and bigger size. Factories with heavy machines use ICCBs to keep important circuits safe.

Some systems need special circuit breakers. Types like SF6, vacuum, and oil circuit breakers use different ways to stop the arc. These breakers are best for medium or high voltage jobs, like in substations or big factories. Each type has its own good points, depending on how it puts out the arc and what the system needs.

Breaker Type | Current Handling Capacity | Trip Settings | Construction/Design Differences | Typical Applications |

|---|---|---|---|---|

Miniature Circuit Breaker (MCB) | Up to 100 amps | Usually fixed, not adjustable | Compact, thermal or thermal-magnetic trip mechanism | Residential, small commercial |

Air Circuit Breaker (ACB) | High current ratings | Adjustable | Uses air for arc extinguishing, easy maintenance | Industrial, utility power distribution |

Insulated Case Circuit Breaker (ICCB) | Higher amp ratings than MCCB | Includes 2-step stored energy mechanism | Entirely plastic frame, no metal on frame | Larger industrial applications |

Other Types (SF6, Vacuum, Oil) | Medium to high voltage | Varies by type | Specialized arc extinguishing methods | Substations, large industrial plants |

MCCBs work well and give strong protection. They use both thermal and magnetic trips to stop overloads and short circuits. This helps keep electrical systems safe in hard places. Many MCCBs, like HAIPART’s, follow strict world rules. They pass extra tests for insulation, contact resistance, and overload tripping. These tests make sure they are safe and reliable.

MCCBs can stop very high fault currents, up to 100kA.

Their trip settings can be changed for different loads.

Other breakers, like MCBs, have fixed settings and lower breaking power.

Solid-state protection is getting more popular. It gives exact trips and better control. Still, MCCBs are used most in factories.

MCCBs are trusted for circuit protection. They are a top pick for important electrical systems.

The ratings and settings of a breaker help it fit many jobs. MCCBs have many current and voltage ratings. Users can change trip settings to match the system’s needs. This helps stop cables from being too big and keeps things safe in different places.

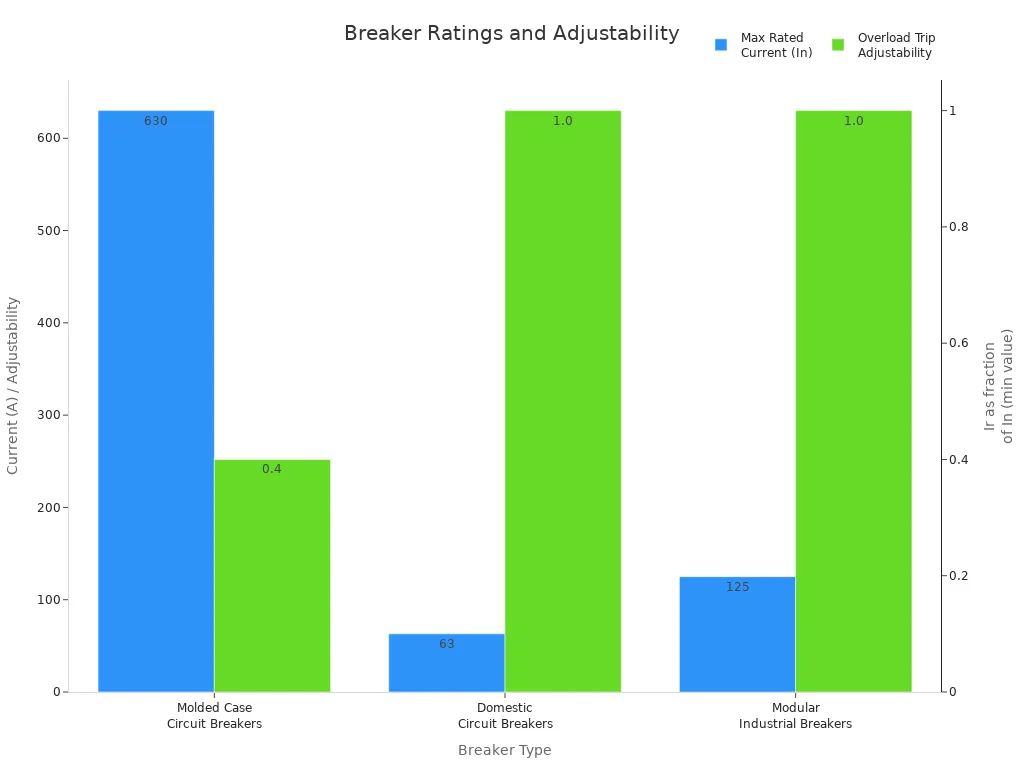

Breaker Type | Rated Current (In) | Rated Operational Voltage (Ue) | Overload Trip-Current Setting (Ir) | Short-Circuit Trip-Current Setting (Im) |

|---|---|---|---|---|

Molded Case Circuit Breakers | High, up to 630A or more | For normal and disturbed conditions | Adjustable: 0.7–1.0 × In (thermal), 0.4–1.0 × In (electronic) | Adjustable or fixed: 2–10 × In, sometimes up to 15 × In |

Domestic Circuit Breakers | Lower, for homes and small offices | For normal conditions | Fixed: Ir = In | Fixed: Type B (3–5 × In), C (5–10 × In), D (10–20 × In) |

Modular Industrial Breakers | Intermediate | For normal conditions | Fixed: Ir = In | Fixed, similar to domestic types |

MCCBs have trip relays you can remove and swap. This makes it easy to change settings for new loads. It also keeps things safe as needs change. Most home breakers have fixed settings and cannot be changed.

How a breaker is built changes how long it lasts and how well it protects. MCCBs use strong thermoset or glass polyester for their cases. This molded case keeps all parts safe and cool. It also protects from dust, water, and tough places.

Aspect | Molded Case Circuit Breakers (MCCBs) | Standard Circuit Breakers |

|---|---|---|

Housing Material | Thermoset composite or glass polyester | Simpler, less robust housing |

Construction Method | Molded case, modular design | Basic, sealed components |

Environmental Protection | High, suitable for harsh conditions | Limited |

Heat Dissipation | Superior, for high-current operation | Less effective |

Mechanical Strength | Robust, for industrial use | Less rugged |

Maintenance and Upgrades | Modular, easy to maintain and upgrade | Components replaced when faulty |

Application Suitability | Industrial and commercial | Residential or light commercial |

Durability Impact | High durability | Lower durability |

MCCBs last longer and need less care than other breakers. They are sealed, so you do not open them for normal checks. Simple jobs like tightening bolts and checking heat keep them working.

MCCBs only need basic checks and to be used by hand once a year.

Other breakers, like low-voltage power ones, need more checks and harder work.

MCCBs are easy to reset after they trip, so power comes back fast.

You can see the big differences between MCCBs and other breakers in real life. MCCBs work best where strong protection and high reliability are needed, like in factories, big buildings, and solar farms. Their high breaking power and changeable settings make them good for motors, generators, and main boards.

MCCBs protect big machines and important systems in factories.

They work well in places with dust, water, or high heat.

Other breakers, like MCBs, are better for homes or small offices with lower power needs.

Air circuit breakers and insulated case circuit breakers are used for bigger or special power systems, but they need more care and space.

HAIPART MCCBs have world safety marks like CE, CB Scheme, CCC, and RoHS. These show they are safe and reliable. Their two trip types and high breaking power make them different from regular breakers.

Picking the right breaker depends on the power needed, the place, and how much protection is wanted. MCCBs give good performance, last long, and can be used in many tough jobs.

Molded case circuit breakers and miniature circuit breakers are used for different jobs. MCCBs can handle much bigger currents, from 15A up to 2500A. They also work with voltages as high as 1000 VAC. This makes MCCBs good for factories and big buildings. MCBs are made for smaller jobs. Their current ratings go from 1A to 125A. They work with voltages up to 415 VAC. Electricians use MCBs in homes and small offices.

Breaker Type | Current Range | Voltage Range |

|---|---|---|

Miniature Circuit Breaker (MCB) | Typically up to 125A | Usually up to 415 VAC |

Molded Case Circuit Breaker (MCCB) | Typically 15A to 2500A | Up to 1000 VAC |

MCCBs are made for strong power systems. MCBs are best for small circuits.

Each breaker type protects in different ways. MCCBs have trip settings you can change for different loads. They use both thermal and magnetic protection. This lets them stop overloads and short circuits fast. MCCBs can handle high inrush currents, which is important for motors and generators. Some MCCBs also have earth-leakage protection. MCBs have fixed trip settings and use a simple air-break method to stop arcs. They work well for basic overload and short-circuit protection in homes. But MCBs cannot handle high inrush currents. They need extra devices for earth-leakage protection.

Feature/Capability | MCCB | MCB |

|---|---|---|

Current Rating | Up to 2,500A | Up to 125A |

Trip Settings | Adjustable | Fixed |

Breaking Capacity | Up to 50 kA | Around 16 kA |

Application | Industrial, commercial | Residential, small commercial |

MCCBs cost more than MCBs. They have advanced features like digital trip units and smart monitoring. This makes them more expensive. Installing and taking care of an MCCB needs skilled workers. These workers need special training, especially for smart features. MCBs are cheaper and easier to take care of. Most people can replace an MCB without special skills. This is why MCBs are popular for homes and small businesses.

Tip: MCCBs are worth the cost for big systems that need strong protection. For simple jobs, MCBs are a good and cheap choice.

When you look at mccb vs acb, you can see a big difference in ampere ratings. Molded case circuit breakers usually work with currents from 10A to 1600A. Some special models can go up to 3000A for bigger jobs. This means MCCBs can protect branch circuits, motors, and low-voltage systems. They are small and simple, so they fit well in smaller places.

Air circuit breakers start at higher ampere ratings. Most ACBs work from 400A up to 6300A. These breakers are bigger and can handle more current. They are best for main power lines and big power networks in factories.

Circuit Breaker Type | Typical Ampere Ratings | Key Characteristics and Application Suitability |

|---|---|---|

Molded Case Circuit Breaker (MCCB) | 10A to 1600A (some up to 3000A) | Small size, simple build, good for branch circuits, motors, and low-voltage systems. Used for lower current and smaller jobs. |

Air Circuit Breaker (ACB) | 400A to 6300A | Bigger size, more features, used for main power lines and big networks. Good for high current, main power, and factories. |

Note: Picking the right ampere rating is important. MCCBs are flexible for lower and medium currents. ACBs are made for the highest current needs.

Mccb vs acb is also different in how they are used. MCCBs are found in offices and smaller factories. They protect circuits for lights, computers, and small machines. Their plastic case keeps them safe and makes them easy to put in small spaces.

ACBs do a different job. These breakers protect main power lines in big factories and data centers. ACBs have smart features like real-time monitoring and can connect to building systems. They can stop big short-circuit currents and work well in tough places, like hot or dusty rooms.

MCCBs: Used for branch circuits, motors, and low-voltage jobs in offices and small factories.

ACBs: Used for main power lines, big machines, and important power systems in large factories.

Choosing between mccb and acb depends on how much current you need and how much protection is needed. MCCBs are best for smaller, less hard jobs. ACBs are better for high current, main power, and places that must always have power.

Tip: For most office and light factory needs, MCCBs work well. For main power in big places, ACBs have the features and power needed.

MCCBs have a strong case made from molded insulation. This case helps them work with currents from 15 to 2500 amperes. MCCBs are trusted and save money for many uses, like homes and small factories. ICCBs are built differently. They use solid insulation that can handle heat. This lets ICCBs work with higher currents, from 800 to 5000 amperes. ICCBs are made to be safer by lowering arc flash risks. They are bigger, so they can have more features. Some features are stored energy systems and short time functions. ICCBs usually follow UL 489 safety rules. Many ICCBs are fixed in place or can be pulled out for repairs. MCCBs let you change trip settings and reset them after a problem. This makes MCCBs good for many jobs. ICCBs are best for places that need extra safety, like big factories.

ICCBs make things safer by stopping arcs inside and using materials that resist heat. MCCBs give strong protection for many types of electrical systems.

The biggest differences between MCCBs and ICCBs are in how people use them. MCCBs are good for managing power in factories and big buildings. They are a cheaper choice for many places. ICCBs work better in places that need to handle a lot of power. Their design makes repairs easier and settings more flexible.

Feature / Aspect | Molded Case Circuit Breakers (MCCBs) | Insulated Case Circuit Breakers (ICCBs) |

|---|---|---|

Current Handling Capacity | Up to 2500 Amps | Up to 5000 Amps |

Operational Flexibility | Fixed trip settings, less adjustable | Adjustable trip settings for varying load conditions |

Maintenance Accessibility | Requires more disassembly for inspection | Easier maintenance with removable covers without full disassembly |

Fire Hazard Protection | Standard protection | Enhanced protection by containing internal arcing |

Typical Applications | Industrial and commercial load management, cost-effective | High-capacity industrial environments requiring flexibility and maintainability |

MCCBs are right for most factories and big buildings. ICCBs are best for places that need lots of power, easy repairs, and more safety.

Picking the right circuit breaker keeps people and equipment safe. Each breaker type works best in certain places. When choosing a breaker, you should think about some key things:

Electrical load rating: The breaker must handle the normal current. It should not trip too early.

Interrupting capacity: The breaker must stop big fault currents. This helps prevent damage.

Physical size: The breaker must fit in the space you have.

Environmental conditions: Some breakers work better with dust or water. Some can handle hot or cold places.

Adjustable trip settings: These help protect systems with changing loads.

Cost-effectiveness and maintenance: Good breakers save money over time. They are also easier to take care of.

Compliance with safety standards: Certified breakers follow safety rules and laws.

Different breakers protect in different ways. MCBs use thermal and magnetic parts for small overloads at home. MCCBs have settings you can change for bigger jobs in factories. ACBs use air to stop arcs in big industrial systems. Picking the right breaker for your system keeps everything safe and working.

Doing regular checks, like looking for rust or loose wires, helps stop problems and keeps the system safe.

Experts suggest some steps for picking and caring for circuit breakers:

Make sure the breaker's voltage matches the system.

Pick a current rating that fits the system. Do not pick one too high or too low.

The interrupting capacity should be as high as the biggest fault current.

Choose a breaker with the right frequency for your system.

Use adjustable trip settings if your loads change.

Check if the breaker can handle dust or heat.

Decide how many poles you need for your system.

Look for breakers that are easy to test and fix.

Plan for the size and how you will mount the breaker.

Checking breakers often, using thermal cameras, and testing trips keep them working well. Change old breakers and keep notes on tests and repairs to stay safe. For big or tricky systems, ask an expert for help. This makes sure everything is put in right and stays safe for a long time.

Picking the right circuit breaker keeps people and equipment safe. The table below shows how MCCBs are different from other breakers:

Feature | MCCB | MCB | ICCB |

|---|---|---|---|

Size | Larger, robust | Small, compact | Large, insulated |

Current Range | Up to 2500A | Up to 125A | Up to 5000A |

Trip Settings | Adjustable | Fixed |

MCCBs, like HAIPART, let you change protection settings. They can stop high currents in tough factory jobs. Picking the right breaker keeps things safe and working well. It also makes sure you follow safety rules. If a project is hard, ask an expert for help. This helps you avoid problems and keeps everything working right.

An MCCB can work with bigger currents. It also lets you change trip settings. An MCB is best for small circuits in homes or offices. MCCBs are used to protect big systems in factories and large buildings.

MCCBs cannot find earth leakage on their own. For this, electricians use earth leakage circuit breakers or residual current devices. These devices notice leakage currents and turn off the power to keep people safe.

Motor protection circuit breakers keep electric motors safe from too much current or short circuits. Factories and workshops use them to help motors run well. These breakers stop damage and help machines work longer.

Residual current circuit breakers watch how electricity moves. If they see a difference between the live and neutral wires, they turn off the power fast. This helps stop electric shocks and fires.

Most homes do not need MCCBs. Electricians usually put in MCBs or residual current devices in houses. MCCBs are better for places that use a lot of power, like factories or big buildings.